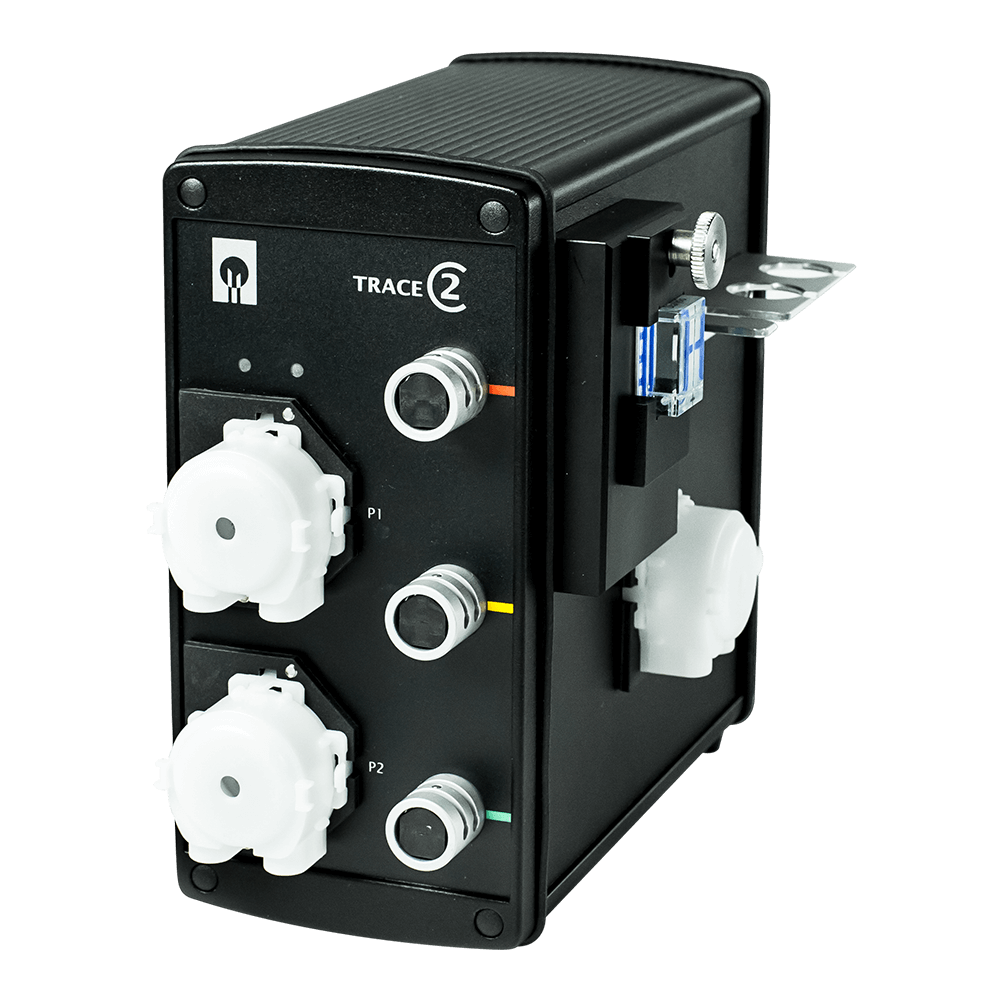

On-Line Fermentation Analyzer

TRACE C2

Monitor key nutrients and metabolites and automatically control substrate feeding in microbial fermentation.

Monitor critical parameters in real time. TRACE C2 offers online monitoring of methanol or ethanol and control of substrate feeding. There’s no direct sampling, so there’s no volume loss. Only real-time insights and real-time control for optimal productivity of your fermentation process.

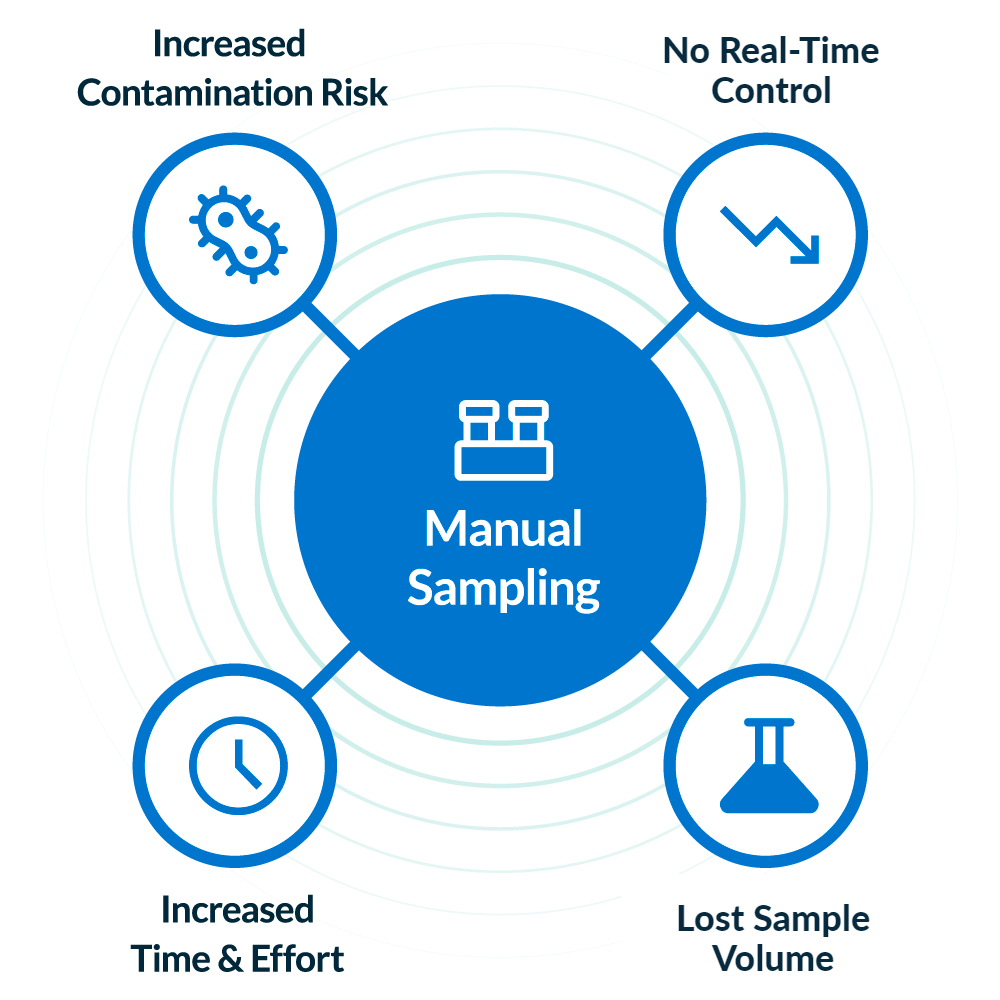

Put Down the Pipette

Manual sampling is time consuming and it rarely gives enough data to fully understand your bioprocess. It also invites contamination risk each time you pull a sample.

It’s Time for Real-Time

With TRACE C2 connected to your fermenter, you can quickly get up and running with 30 automated measurements per hour. No pipettes. No contamination risk. No babysitting your fermenters during off-hours.

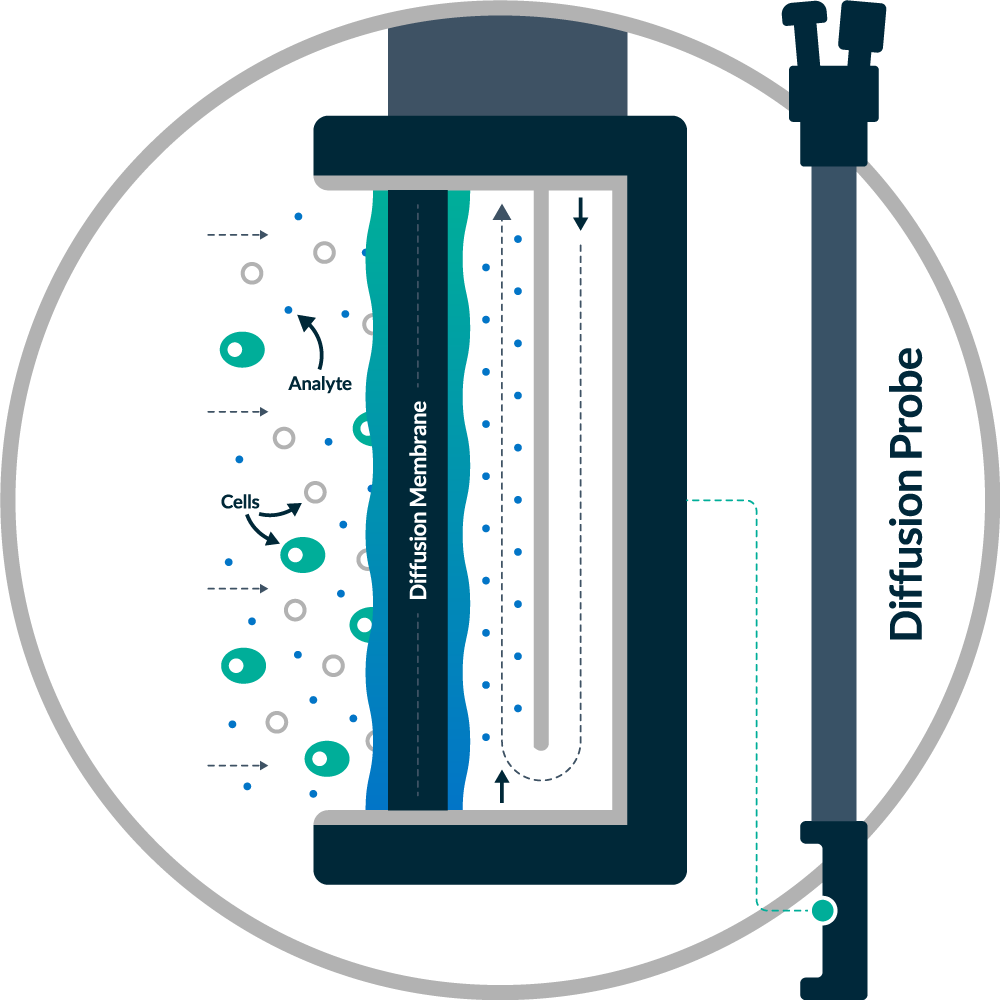

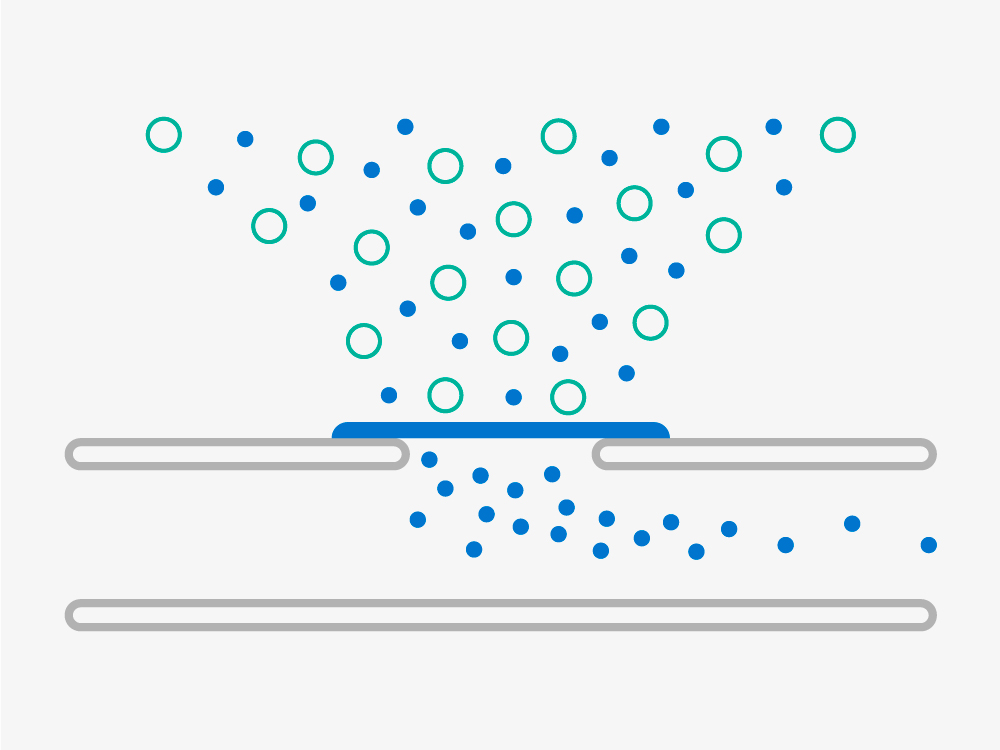

Precise & Sterile Measurement

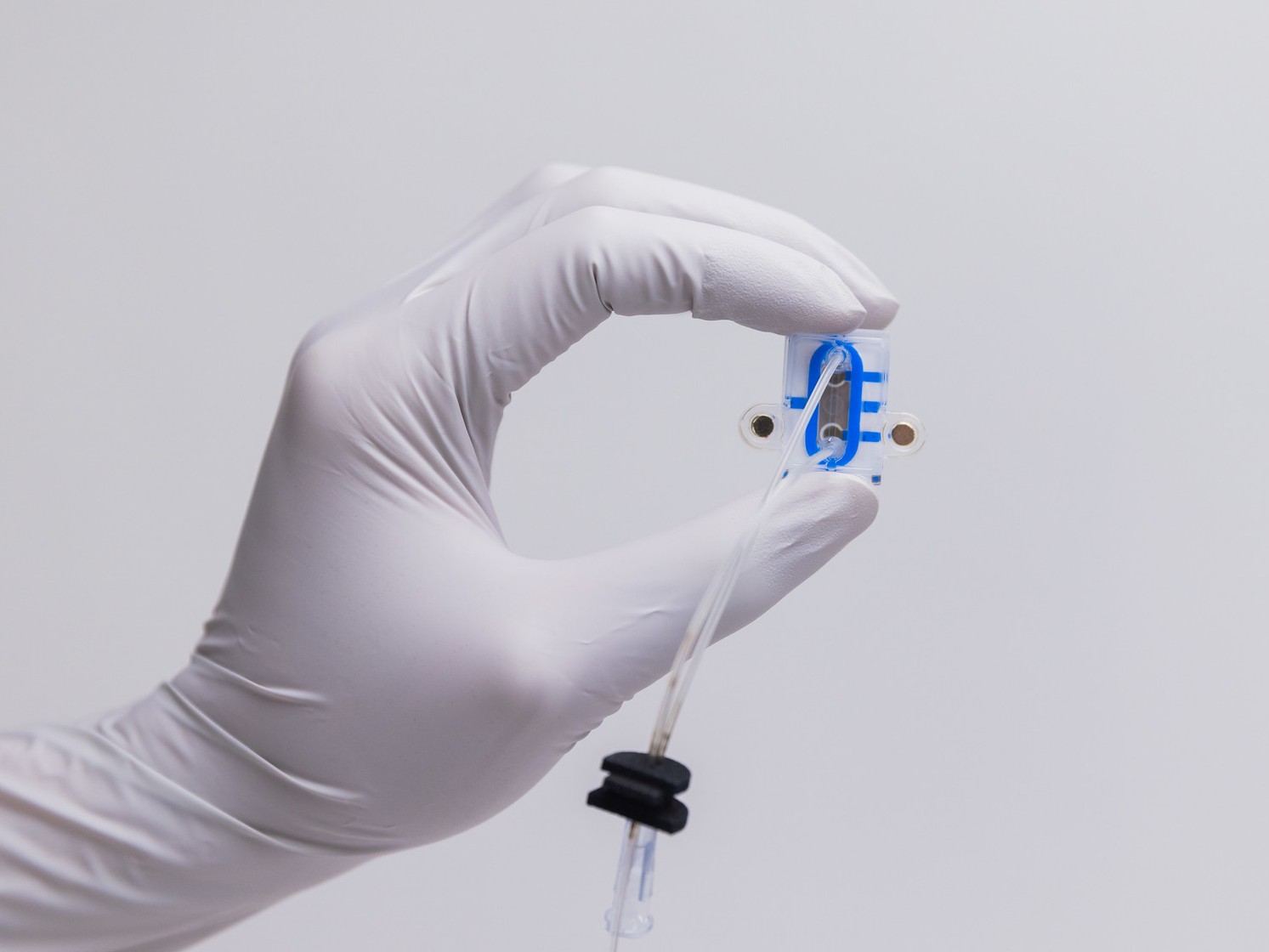

Diffusion probe is installed in a fermenter and connects to TRACE C2 measurement cell with a pre-configured tubing set. Only methanol or ethanol molecules are small enough to diffuse through the semi-permeable membrane into the buffer fluid, so there is no loss of bioreactor volume and no increased risk of process contamination.

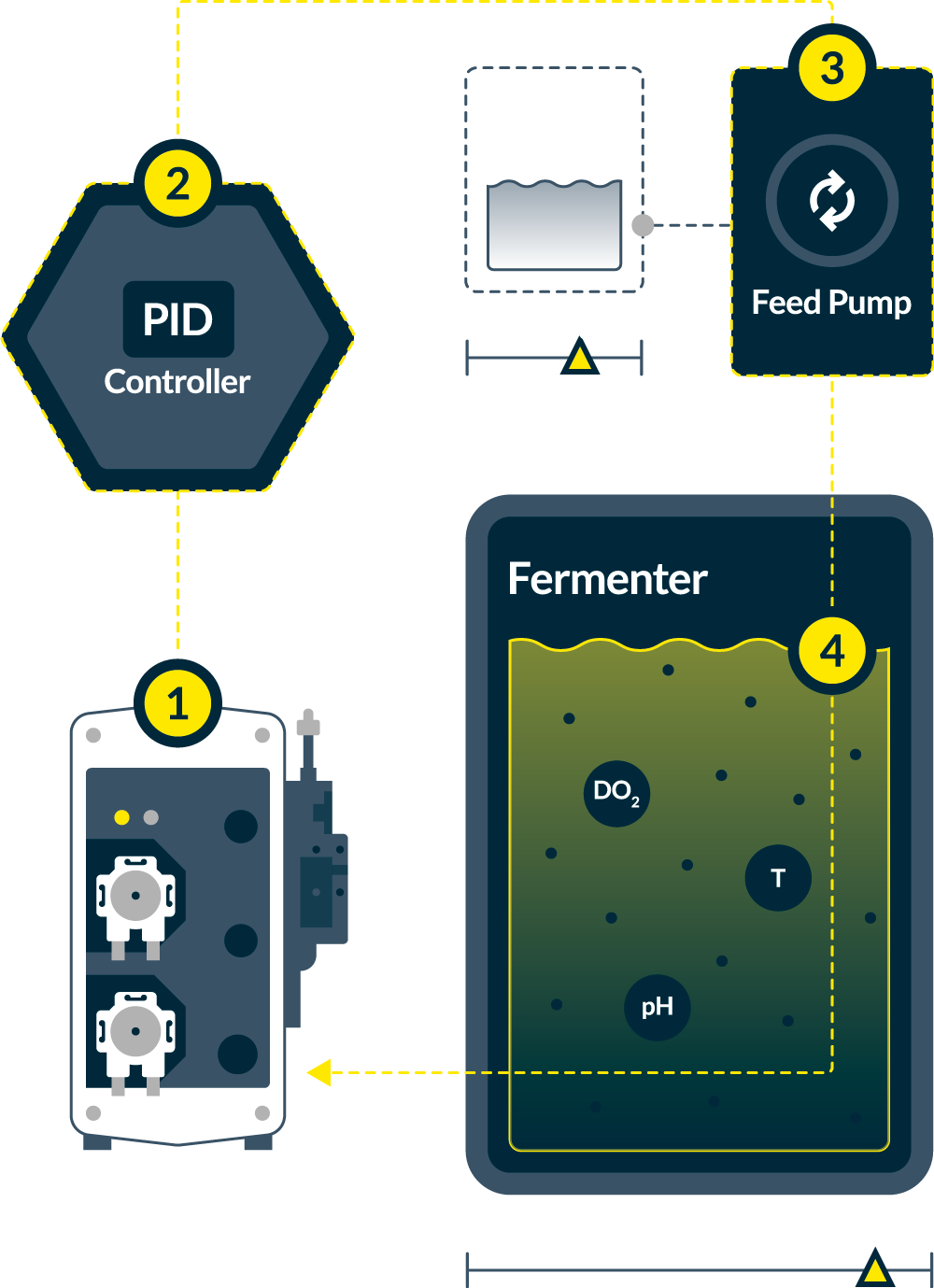

Step 1:

Small quantity of clean buffer solution is drawn from the reservoir and sent to the probe.

Step 2:

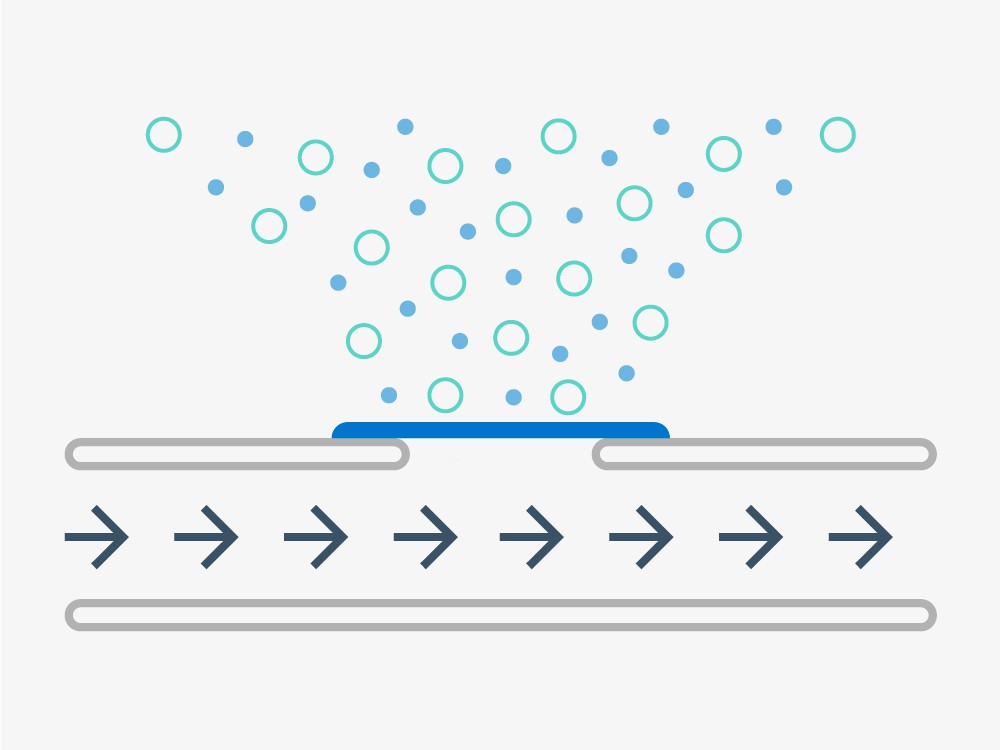

Flow of buffer is paused allowing methanol or ethanol to diffuse through the membrane into the buffer fluid.

Step 3:

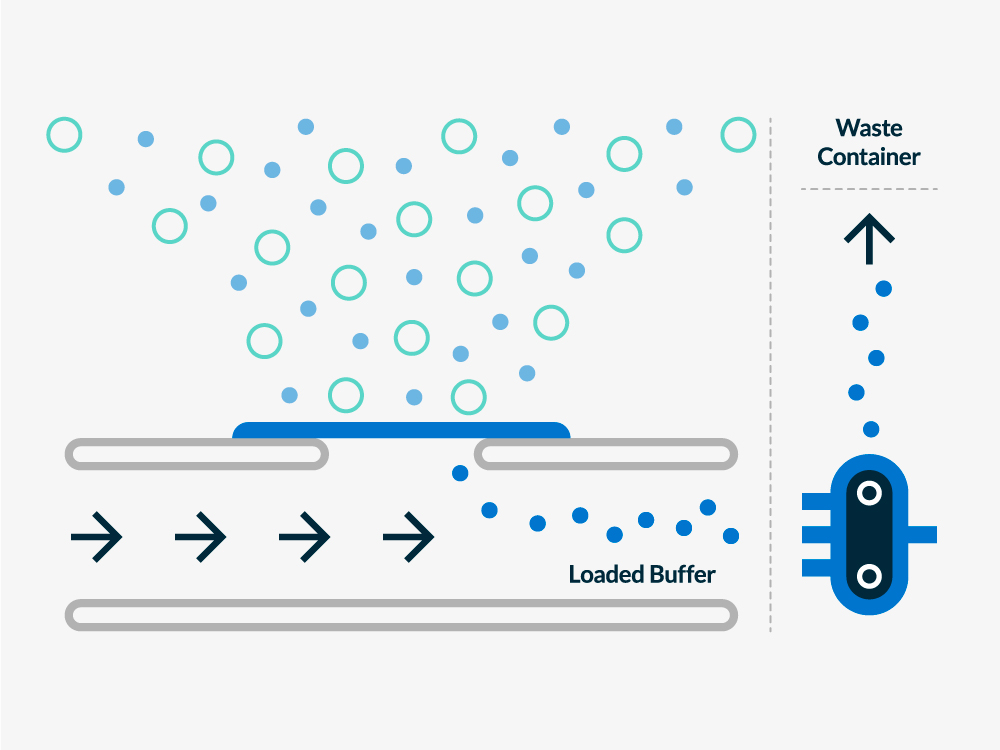

Flow is resumed, the loaded buffer is delivered to the measuring cell

Step 4:

Analyte concentrations are measured by the biosensor, and used buffer is disposed into the waste container

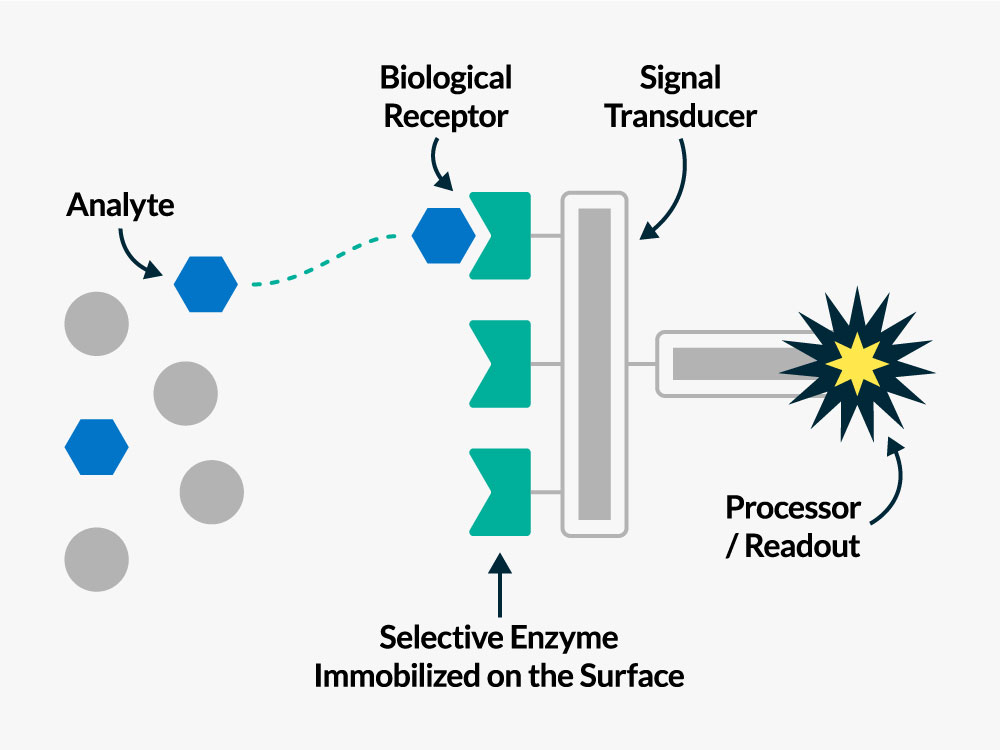

Trusted Biosensor Design

Biosensors’ enzymatic recognition and selectivity for methanol or ethanol generates an electrical signal proportional to analyte’s concentration.

- Sensor type: Enzyme-based electrochemical biosensor

- Methanol measurement range: From 0.5 to 20 g/L concentration

- Ethanol measurement range: From 1 to 40 g/L concentration

Out-of-the-Box

Feeding Automation

High-frequency on-line measurement enables automated control of feeding to maintain optimal concentration of nutrients while preventing negative effects of metabolites on process yield.

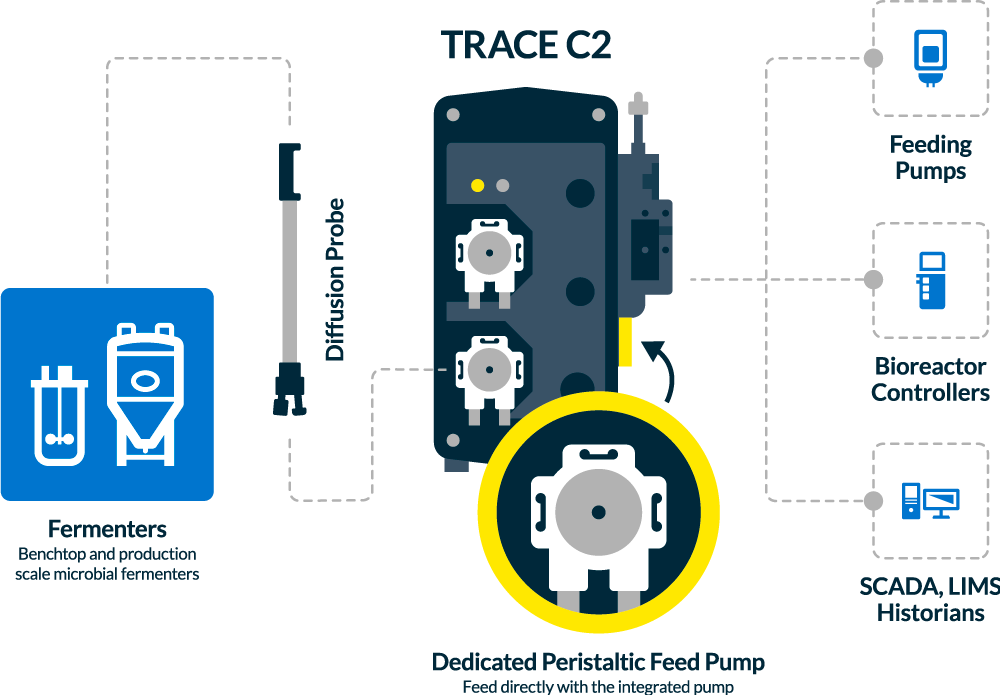

TRACE C2 features a dedicated on-board peristaltic pump and an integrated PID controller that can be used for feeding substrates without any additional auxiliary equipment. Multiple analog and digital communication options facilitate integration with fermenter controllers, external pumps, SCADA and other OPC UA compatible systems.

Ready to Integrate

Multiple process interface options make it easy to integrate TRACE C2 with most types of microbial fermenters.

How Will You Use TRACE C2?

Monitor key nutrients and metabolites on-line and control feed automatically. TRACE C2 Control lets you maintain optimal fermentation process conditions for laboratory or industrial cultivations of microorganisms.

Featured Resources

Ethanol Dialysis

The online analyzer TRACE C2 Control allows a rapid and precise determination of the Ethanol concentration in the fermenter.

Methanol Dialysis

The online analyzer TRACE C2 Control allows a rapid and precise determination of the methanol concentration in the fermenter and provides the tools for a quick set-up of a feed control strategy

Customer Support Portal

The My 908 portal gives scientists quick access to important resources like the latest software upgrades, product guides, and training materials.

Frequently Asked Questions

What is the risk for contamination in a GMP environment? Can I sterilize the probes?

Manual sampling always carries a greater risk of process contamination than on-line measurement with sterilized diffusion probes. Reusable probes and flow cells are steam autoclavable and their performance has been demonstrated in GMP applications. A great advantage of the TRACE diffusion technology is that it does not consume any media, making closed loop control possible for very small vessels.

How much cleaning, sterilizing and calibration do I need to do with TRACE devices?

TRACE C2 is a compact device and utilize preconfigured single-use tubing sets. The tubing sets connect to calibration standards for automated calibration and recalibration at user-specified times or intervals through the duration of the batch. The only components that require sterilization are the reusable diffusion probes and flow cells. Single-use probes and flow cells are also available.

How does the feedback control loop automate substrate feeding based on on-line measurements?

On-board PID and On/Off controllers enable direct feedback control of substrate feeds. For small and medium size reactors, the integrated peristaltic feed pump can be used to feed substrates. For larger reactors or high substrate consumption rates, larger external pumps can be directly connected via the digital or analog outputs. Alternatively, if a SCADA system or dedicated bioreactor controller is available, the measurement results can be instantly transferred over analog (0-10V or 4-20 mA) or digital (Modbus TCP or OPC UA) signals.

Are TRACE systems available outside the US, and do you provide global technical support?

TRACE products and support are available for purchase directly from 908 Devices in North America and Europe and through a network of distributors

Can TRACE be used at pilot or GMP scale?

Yes. Several of our customers use TRACE technology in clinical and production GMP facilities. TRACE control software is CFR 21.11 compliant and all components meet regulatory requirements for use in GMP applications.

I simultaneously operate 4 bioreactors/fermenters, can I multiplex TRACE C2 to all 4 or do I need a sperate device for each vessel?

Yes. While we recommend that a dedicated TRACE C2 device is connected to each fermenter for independent operation as well as redundancy, multiplexable TRACE systems are available for interfacing with up to 4 vessels.

Can the transport buffer solution enter the process medium during measurement?

Bulk transport buffer solution cannot ingress into the process medium because the membrane is only permeable to very small molecules. However, a small number of salt ions from the buffer solution may cross the membrane barrier but wouldn’t have any detectible effects on the bioreactor conditions.

email Subscribe to Our Communications Signup to receive new product updates, technical tips and more.