On-Line Glucose & Lactate Analyzer

MAVEN

Get faster process insights and dynamic control of substrate feeding without the loss of bioreactor or fermenter volume.

Keep Your Cells Happy

Fluctuations in glucose levels, associated with infrequent measurements and bolus feeding, may cause metabolic deregulation and undesirable process deviations.

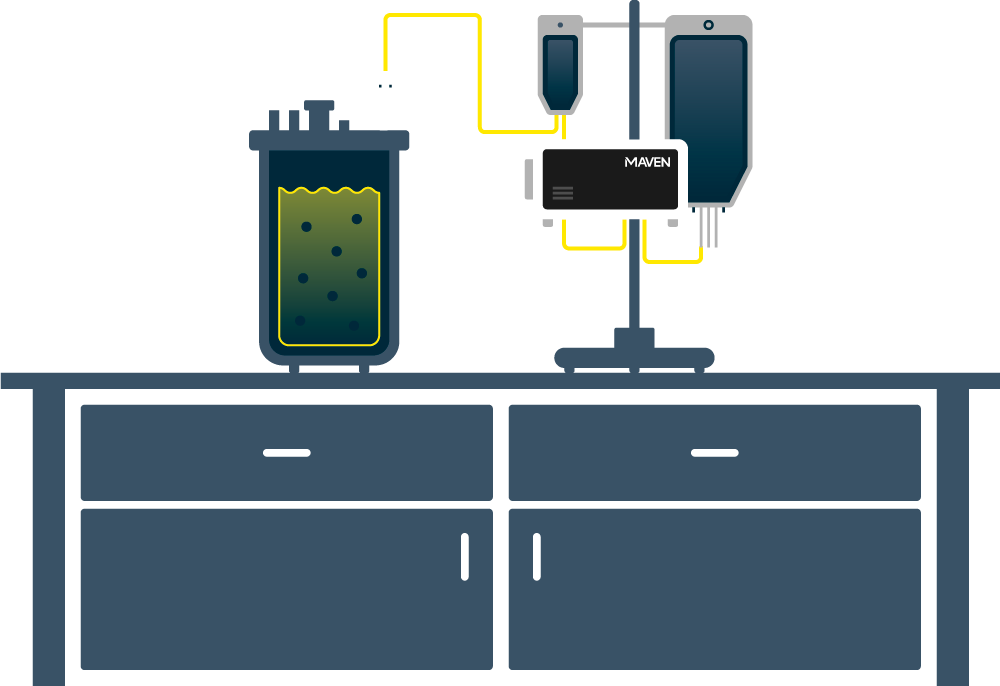

That’s where MAVEN comes in. It has your back, automatically monitoring and controlling glucose and lactate concentrations, helping you realize your PAT strategy.

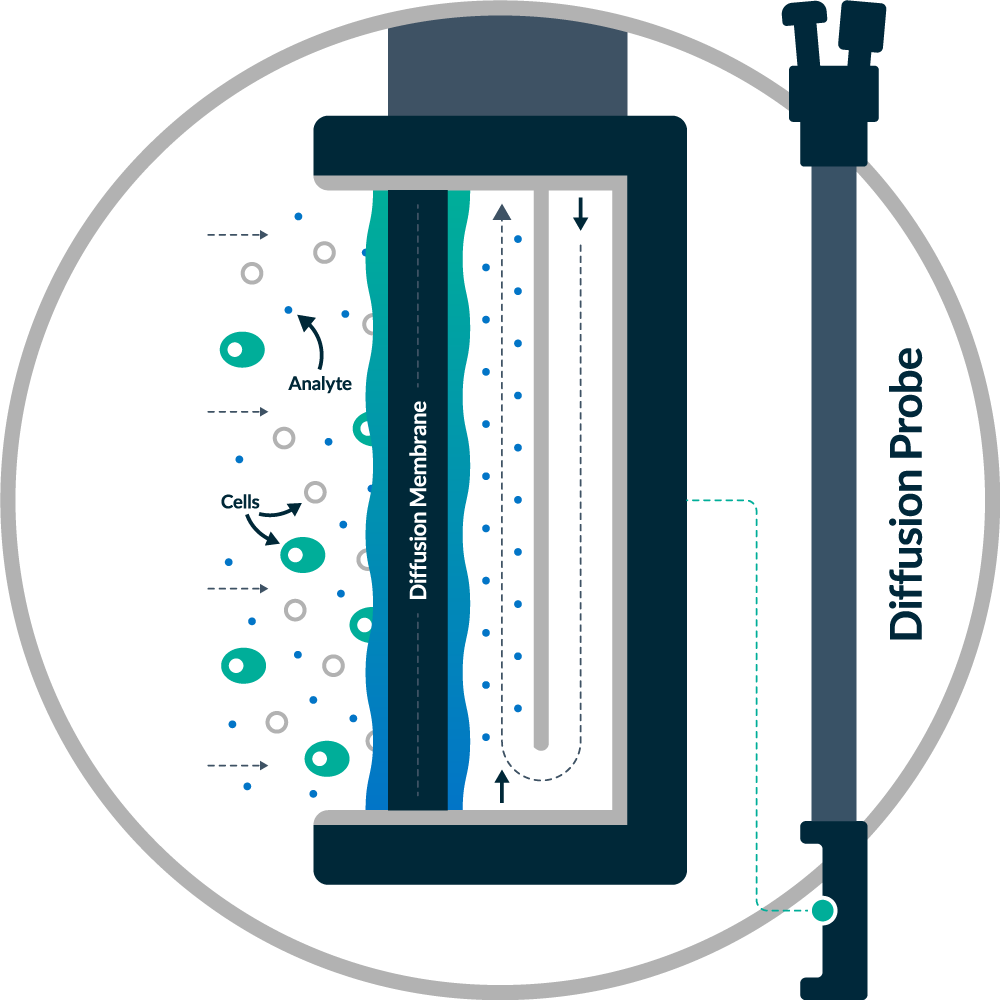

Precise & Sterile Measurement

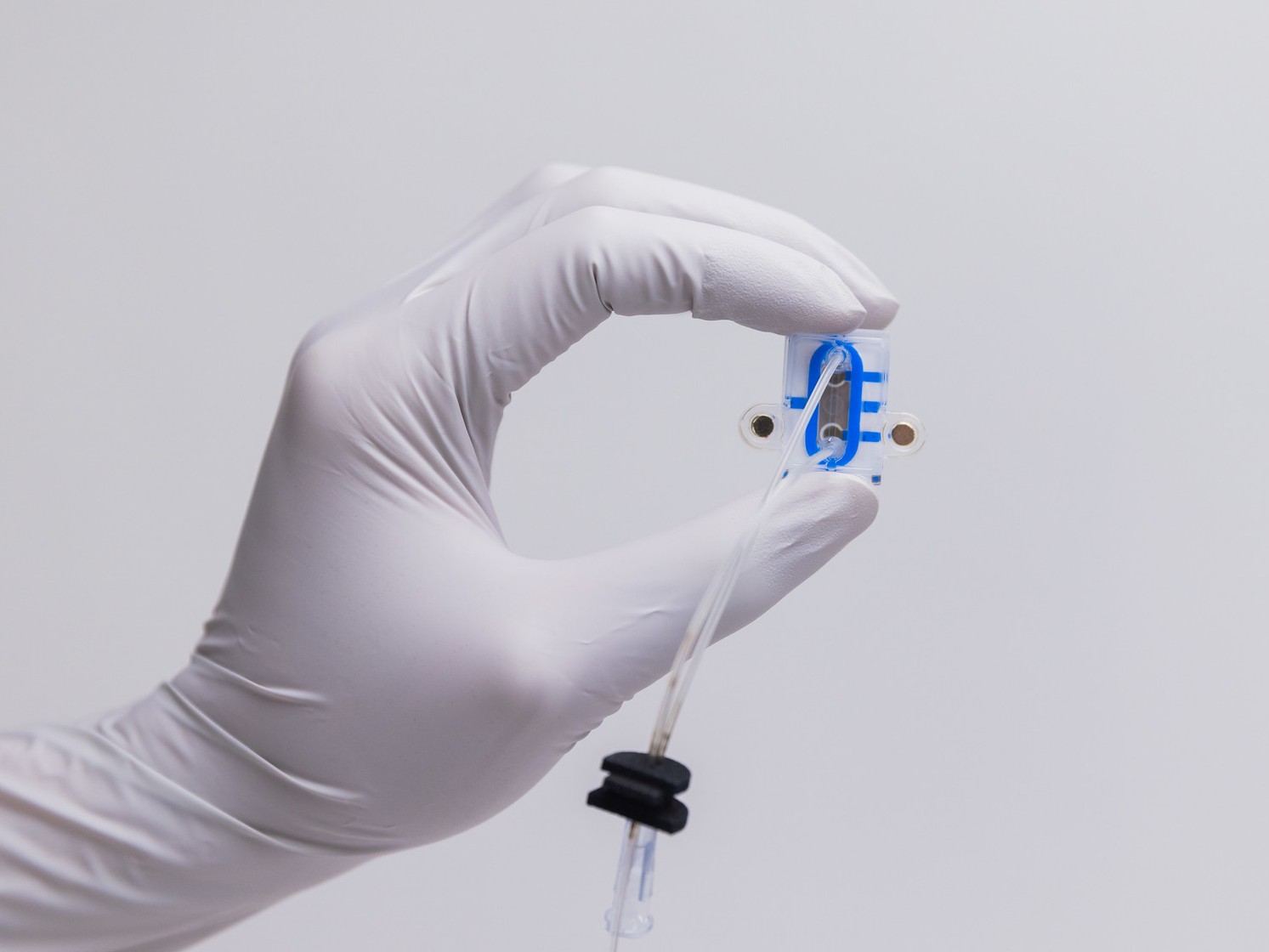

MAVEN’s measurement cell connects to a diffusion probe installed in your bioreactor via a pre-configured tubing set. Only glucose and lactate molecules are small enough to diffuse through the semipermeable membrane into the buffer fluid, meaning there is no loss of bioreactor volume and no increased risk of process contamination.

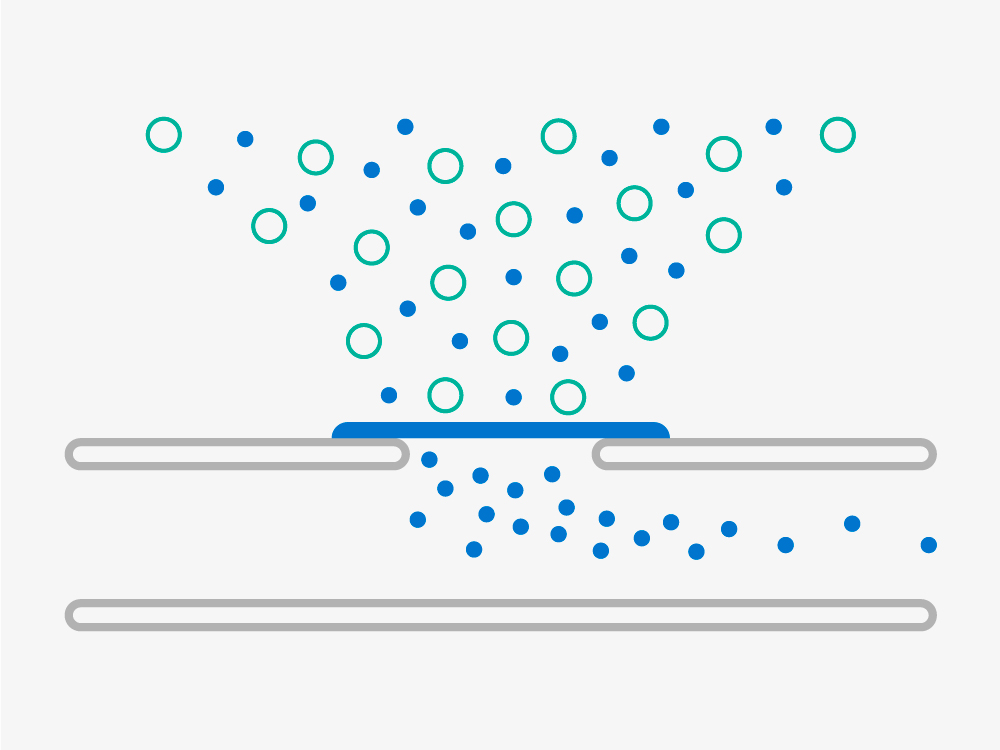

Step 1:

Small amount of clean buffer solution is delivered from the buffer bag into the diffusion probe

Step 2:

Buffer flow is paused and analyte molecules diffuse through the membrane into the buffer fluid

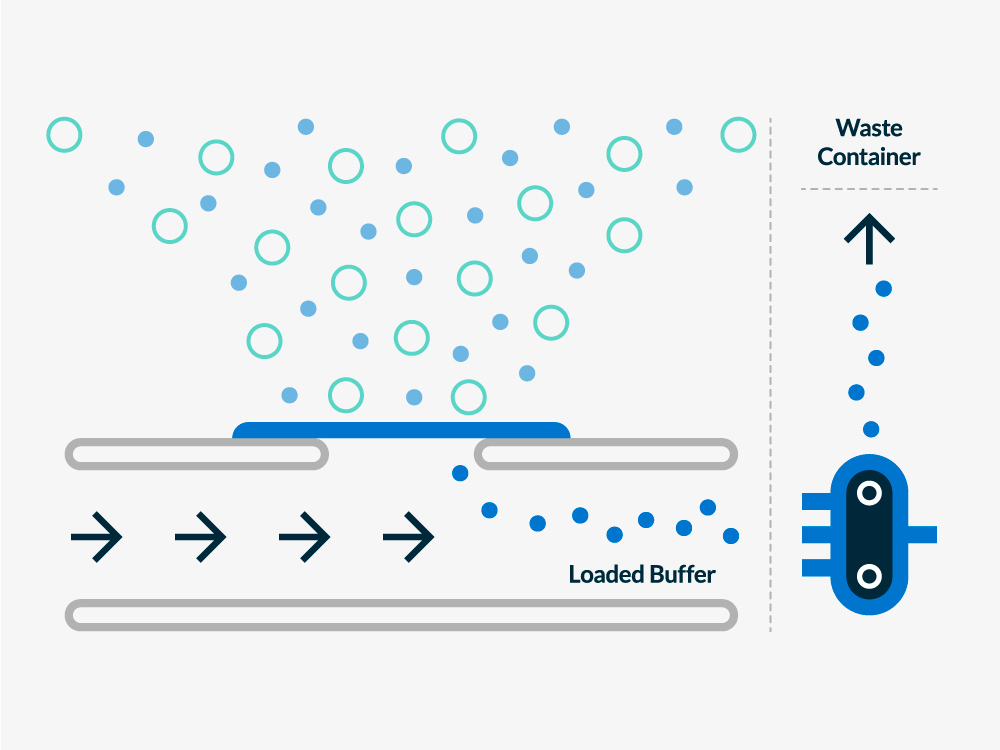

Step 3:

Flow is resumed, the loaded buffer is delivered to the measuring cell

Step 4:

Analyte concentrations are measured by the biosensor, and used buffer is disposed into the waste container

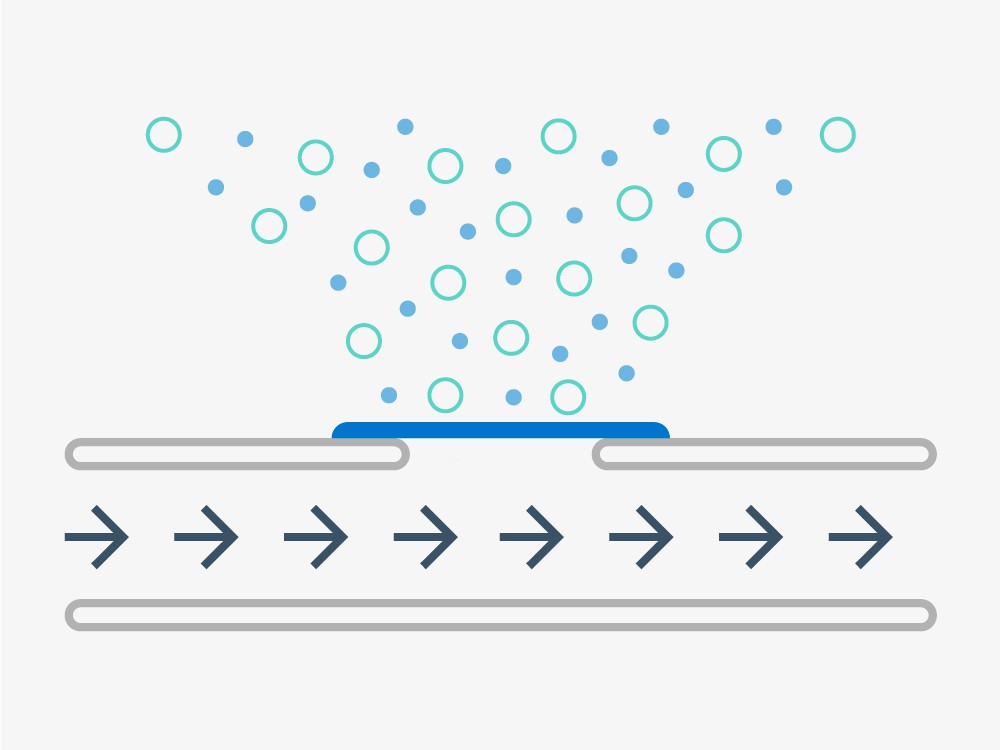

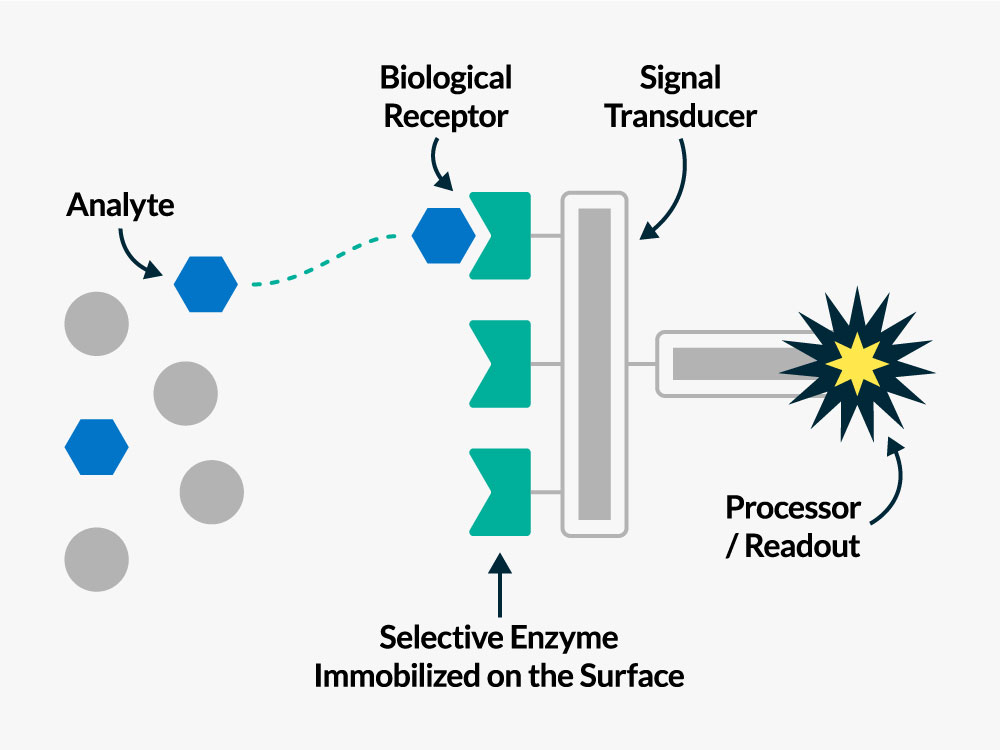

Trusted Biosensor Design

Biosensors’ enzymatic recognition and selectivity for glucose and lactate generates an electrical signal proportional to analyte’s concentration.

- Sensor type: Enzyme-based electrochemical biosensor

- Glucose measurement range: From 0.01 to 40 g/L concentration

- Lactate measurement range: From 0.05 to 10 g/L concentration

Facing restricted lab budgets while expectations, standards, and technology advance?

908 Devices understands your challenge, and we want to help you get to market faster with results in minutes, not months. Contact us today for a complimentary offer.

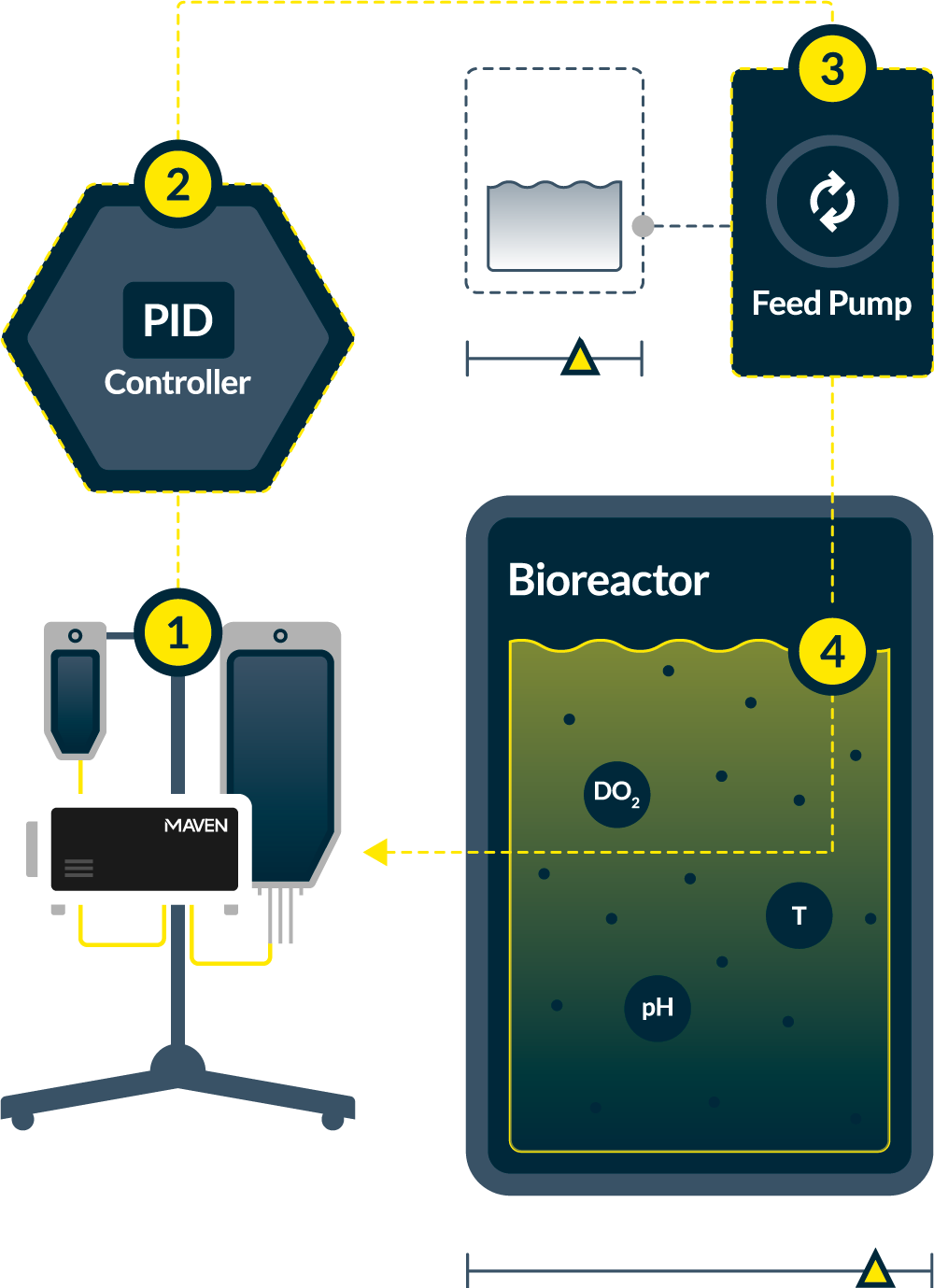

Plug-and-Play

Feeding Automation

In addition to providing real-time measurements, MAVEN comes with integrated PID and on/off controllers that enable out-of-the-box feeding automation. Just connect MAVEN to an external feed pump and configure control setpoints.

- Integrated PID and On/Off controllers for out-of-the-box feeding automation

- Digital communication via OPC UA or Modbus TCP

- Standard analog outputs with milliamp or voltage signals

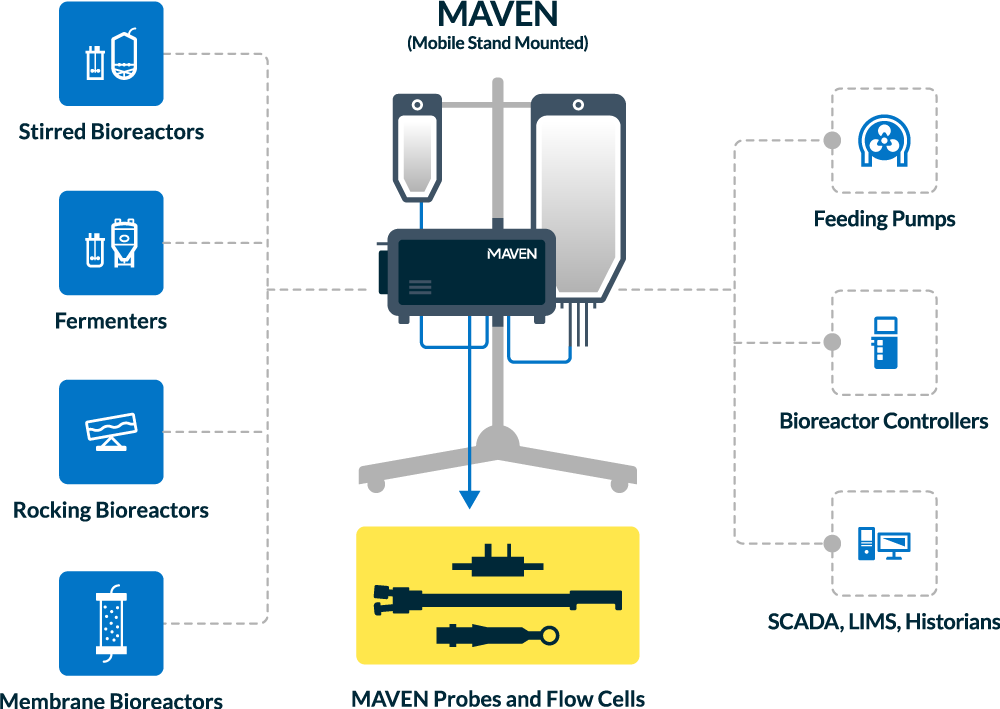

MAVEN Loves to Collaborate

Reusable autoclavable and single-use probes and flow cells make MAVEN compatible with most types and sizes of bioreactors and fermenters.

Improve process understanding and develop process control and feeding strategies in the lab and use the same PAT technology to achieve a more robust process control in clinical and commercial manufacturing.

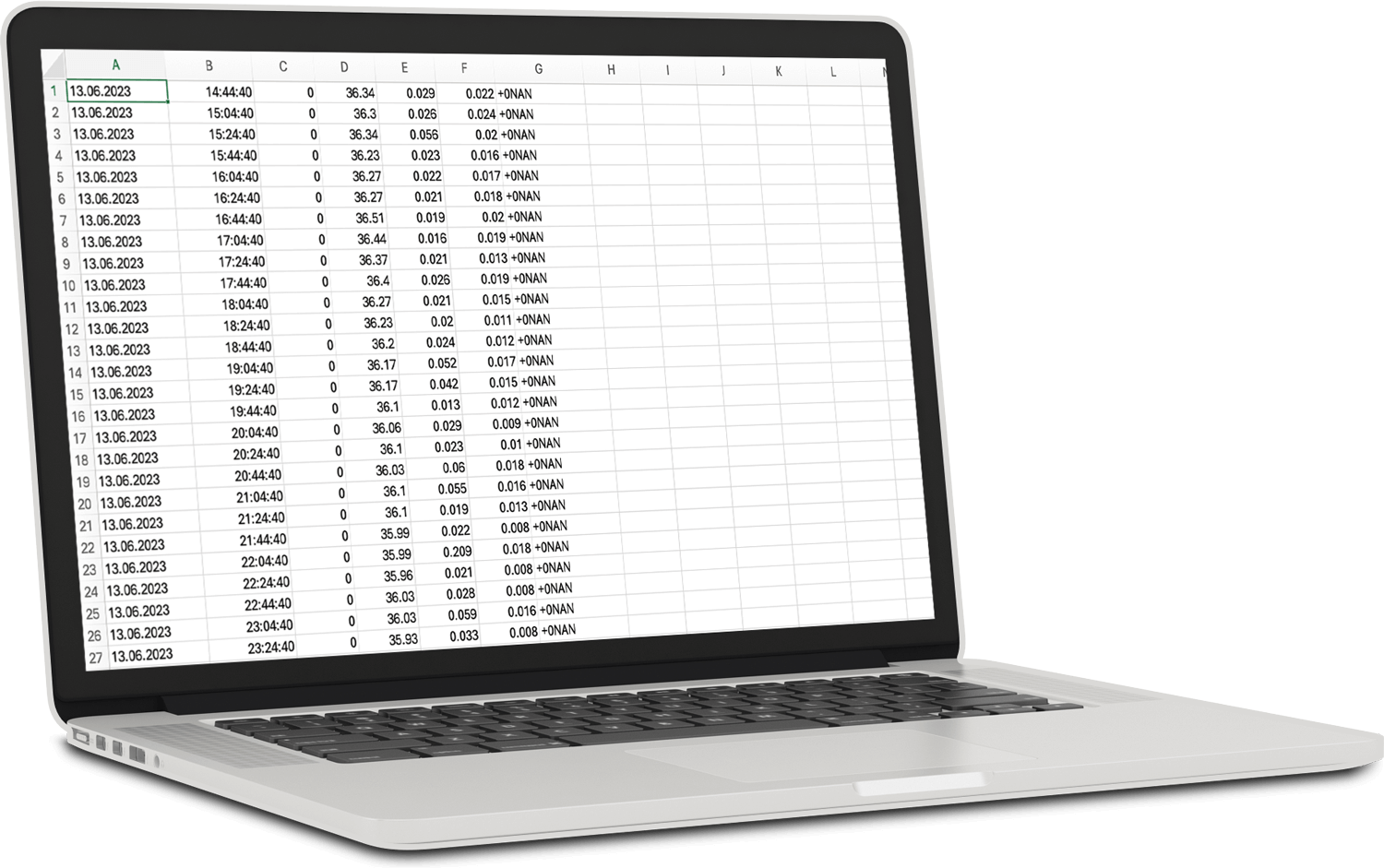

Expedite Data Analysis

MAVEN users with access to the JMP statistical software package are able to expedite time-course data visualization and compare runs. MAVEN users can download the add-in tool from the 908 Devices customer support portal or visit the JMP site to obtain a JMP software trial.

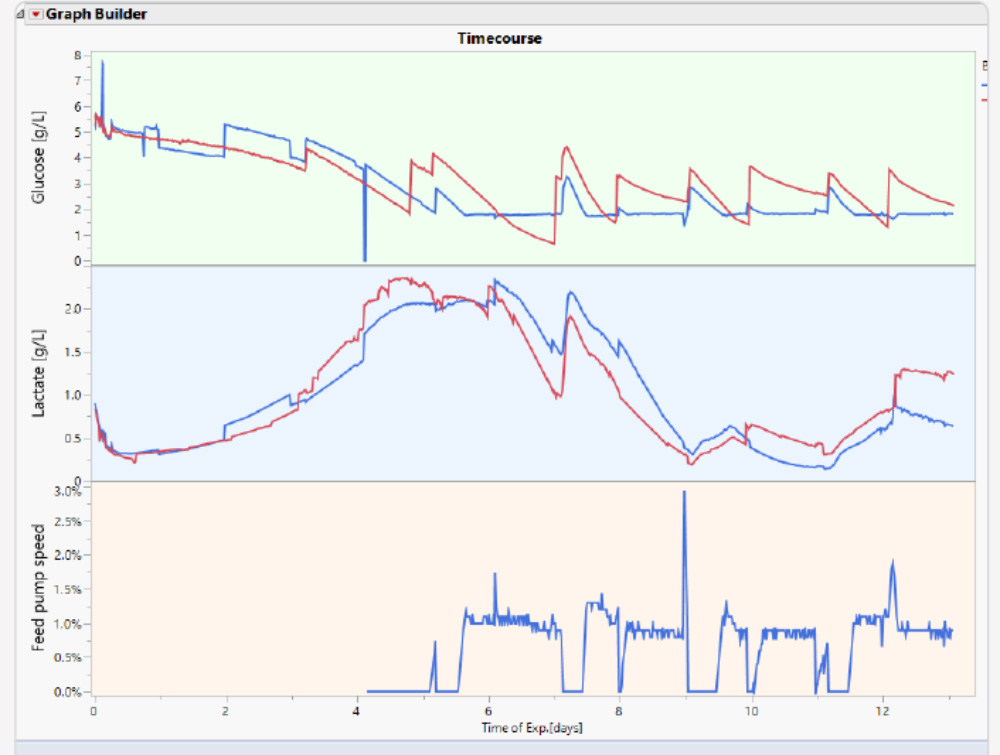

MAVEN Data Visualization

MAVEN data files are data rich from frequent on-line measurements of glucose and lactate.

908 Devices Add-in, with JMP Statistical Discovery

Visualize time-course data for glucose, lactate, and display the glucose feed-pump speed for the duration of the run. Compare the information run- to-run.

Consumables & Accessories

MAVEN systems are highly configurable. Multiple stainless steel probe lengths and bioreactor port adopters are available. Single-use probes and flow cells are gamma sterilizable and can be preinstalled on bioreactor bags by the OEMs.

How Will You Use MAVEN?

MAVEN is here to give you control and help you maintain optimal cell culture or fermentation process conditions for laboratory or industrial cultivations of microorganisms and cell cultures.

Featured Resources

MAVEN Brochure

MAVEN offers monitoring and control of glucose and lactate concentrations during cell culture and fermentation. Download this brochure to learn more.

MAVEN Specification Sheet

Get all the MAVEN specifications, including measurement range, physical dimensions, and software requirements.

MAVEN Product Video

If glucose and lactate measurements run your lab’s schedule, it’s time to meet MAVEN.

Now Starts Now: The Future of Glucose & Lactate Measurement

Learn how MAVEN addresses the challenges of on-line nutrient and metabolite monitoring and control.

Customer Support Portal

The My 908 portal gives scientists quick access to important resources like the latest software upgrades, product guides, and training materials.

Frequently Asked Questions

What is the risk for contamination in a GMP environment? Can I sterilize the probes?

Manual sampling always carries a greater risk of process contamination than on-line measurement with sterilized diffusion probes. Reusable probes and flow cells are steam autoclavable and their performance has been demonstrated in GMP applications. A great advantage of the diffusion technology is that it does not consume any media, making closed loop control possible for very small bioreactors.

How much cleaning, sterilizing and calibration do I need to do with the devices?

The compact devices utilize preconfigured single-use tubing sets. The tubing sets connect to a calibration standard for automated recalibration at user-specified times or intervals throughout the duration of the batch. The only components that require sterilization are the reusable diffusion probes and flow cells. Single-use probes and flow cells are also available and can be pre-sterilized.

How does the feedback control loop automate substrate feeding based on on-line measurements?

On-board PID and On/Off controllers enable direct feedback control of substrate feeds. External pumps can be directly connected via the digital or analog outputs. Alternatively, if a SCADA system or dedicated bioreactor controller is available, the measurement results can be instantly transferred over analog (0-10V or 4-20 mA) or digital (Modbus TCP or OPC UA) signals.

Are MAVEN systems available outside the US and do you provide global technical support?

MAVEN products and support are available for purchase directly from 908 Devices in North America and Europe and through a network of distributors.

I simultaneously operate more than one bioreactor or fermenter, can I multiplex MAVEN to multiple vessels?

At this time, each bioreactor or fermenter would need a dedicated MAVEN device.

Can the transport buffer solution enter the process medium during measurement?

Bulk transport buffer solution cannot ingress into the process medium. However, a small number of salt ions from the buffer solution may cross the membrane barrier but would not have any undesirable effects on cells or micro-organisms.

email Subscribe to Our Communications Signup to receive new product updates, technical tips and more.