Process Analytical Technology for In-line Bioprocess Analysis

MAVERICK

This easy-to-use process analytical technology device offers in-line bioprocess analysis and control with no complex modeling. Measure multiple critical parameters across media, across processes, across mammalian cell lines, across scales.

All In-line Gain, No Modeling Pain

MAVERICK is powered by Raman spectroscopy and a purpose-built de novo model. The de novo model is explicitly built on media chemistries and device physics, not on empirical data. It automatically interprets the spectra and quantifies process parameters enabling simultaneous measurements of glucose, lactate, and total biomass. This is achieved without the costs, complexities, and risks associated with conventional Process Analytical Technology (PAT) methods. There is no need to grapple with complex empirical models, reagents, or unreliable auto-sampling systems to implement in-line bioprocess analysis.

How the De Novo Model Works

The MAVERICK measurements are based on a de novo model. This model was developed from first principles without empirical observation/calibration in bioprocesses with any particular media. The de novo model considers both static and dynamic parameters measured during the actual bioprocess runs. One of the static parameters is a formulary which includes the spectral characteristics of many chemical components in media. These include glucose, lactate, and other cell culture media components detectable by Raman. The dynamic parameters include adapting to changes in environmental factors such as ambient light, temperature, and turbidity, including cell based fluorescence. It also accounts for the characteristics of each unique device from an optical, electronic, and measurement error model perspective.

Real-time Analysis in Minutes

Measure critical bioprocess parameters now, not in weeks or months. No bioprocess runs to collect Raman spectra. No modeling required. There’s an easier way–with MAVERICK’s purpose-built de novo model. Get actionable process parameters in three easy steps: calibrate, autoclave, and start your bioprocess run. These videos show you how.

Calibration

Utilize two standards to calibrate and qualify MAVERICK.

Autoclave

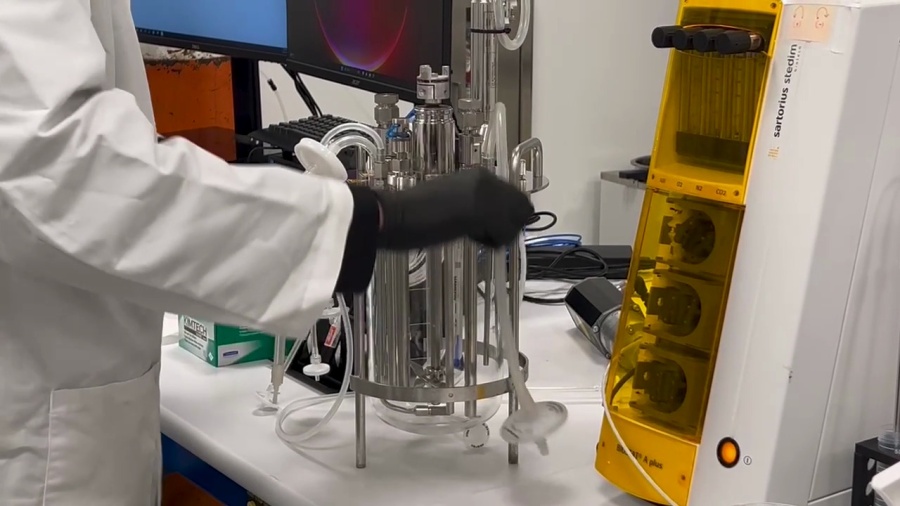

Prepare your bioreactor and MAVERICK probe.

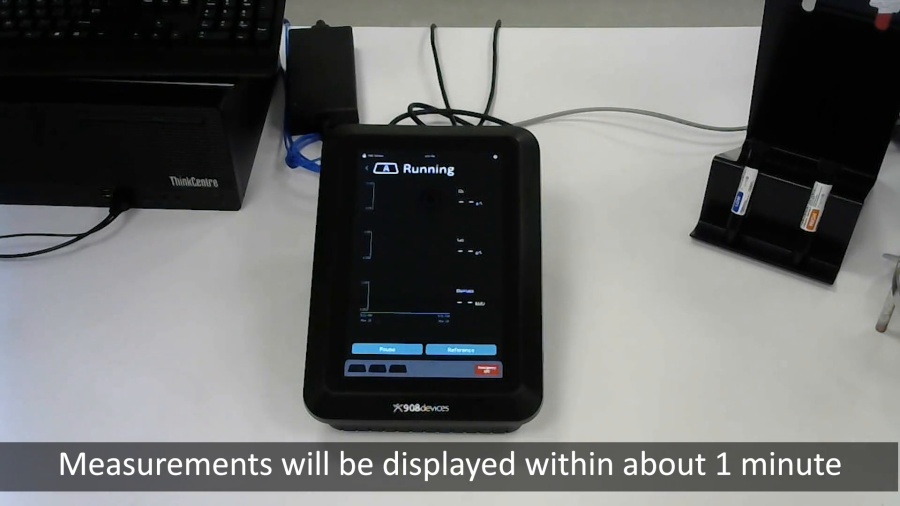

Start Bioprocess Run

Connect the MAVERICK probe to your bioreactor and begin monitoring process parameters. Measurements will be displayed in minutes.

Process Analytical Technology (PAT) Made Easy

While in-line process analytical technology (PAT) offers many benefits, adoption has been hindered by technical challenges, integration issues, and significant implementation costs.

MAVERICK addresses all these issues, ushering in an era of accessible, continuous monitoring of multiple parameters. With MAVERICK, your team can stay at the forefront of Bioprocessing 4.0 and fully harness the advantages of real-time in-line bioprocess analysis (bioreactor monitoring) and control. Intuitive setup and user-friendly interface means there is no training barrier to overcome.

MAVERICK – Easy to Learn, Easy to Use

MAVERICK is intuitively designed for ease of use, requiring no prior experience with Raman spectroscopy or chemometric modeling. It features a user-friendly hub with a high-resolution color touchscreen, CFR 21 Part 11 compliant software, and an intuitive interface that simplifies in-line bioprocess analysis. With MAVERICK, mastering bioprocess monitoring is straightforward and efficient.

Instant Raman, Ready in Minutes

MAVERICK offers all the advantages of Raman-based process analytical technology (PAT) without the cost and complexities associated with developing “black box” empirical calibration models, required by conventional process spectroscopy-based methods. While it can take months and a dedicated team of experts to build and validate a robust empirical calibration model—MAVERICK only takes a simple two-point probe calibration to begin monitoring multiple key process parameters in most types of bioreactors. Just take it out of the box, and you’re already halfway through the setup process.

MAVERICK Setup: Complete in Less Than 1 Day

Start monitoring multiple process parameters in just four simple steps

STEP ONE

Take MAVERICK out of the box and connect components

STEP TWO

Perform two-point calibration with the standard

STEP THREE

Autoclave the probe body with the bioreactor

STEP FOUR

Reconnect the probe

You Are Ready to Monitor Multiple Process Parameters

Traditional Raman Setup: Takes 18 to 60 Months

The calibration model requires revalidation for any significant change in process conditions

STEP ONE

Unbox the instrument and connect the components

STEP TWO

Calibrate and standardize probe optics

STEP THREE

Autoclave the probe with bioreactor

STEP FOUR

Reconnect the probe and prepare the bioreactor runs

STEP FIVE

Collect Raman spectra from multiple bioreactor runs

STEP SIX

Extract samples and collect reference measurements

STEP SEVEN

Build multivariate empirical calibration model

STEP EIGHT

Validate model performance

You Are Ready to Monitor Process Parameters

Already Have Raman Implemented & Having Trouble?

MAVERICK removes the need to maintain models and simply works across processes, scales, devices, and probes. Because it is a commercial off-the-shelf system (COTS), it allows for easy measurement method validation, unlike complex empirical models. Experience a cost-effective solution with little to no device maintenance. MAVERICK delivers a robust and scalable Process Analytical Technology (PAT) solution that helps advance your bioprocess through the pipeline to commercialization.

Multiplex Flex

Connect up to six measurement modules to a single MAVERICK hub to monitor process conditions and control feeds across multiple bioreactors independently and simultaneously in real-time. This setup saves valuable bench space and boosts efficiency.

Reduced Budget But Increased Pressure?

We understand the challenges you face and are ready to help. By streamlining your bioprocess development from months to minutes, 908 Devices can significantly reduce your costs and enhance efficiency. Contact us today to learn more about our complimentary offer and start saving.

Walk-Away Automation with MAVERICK

Control feeding pumps directly or relay the measurements to an existing automation or data acquisition system. Integration is simplified with analog and digital connectivity via Ethernet or OPC UA. Optional remote monitoring allows you to securely check on your bioreactors from anywhere, anytime, 24/7.

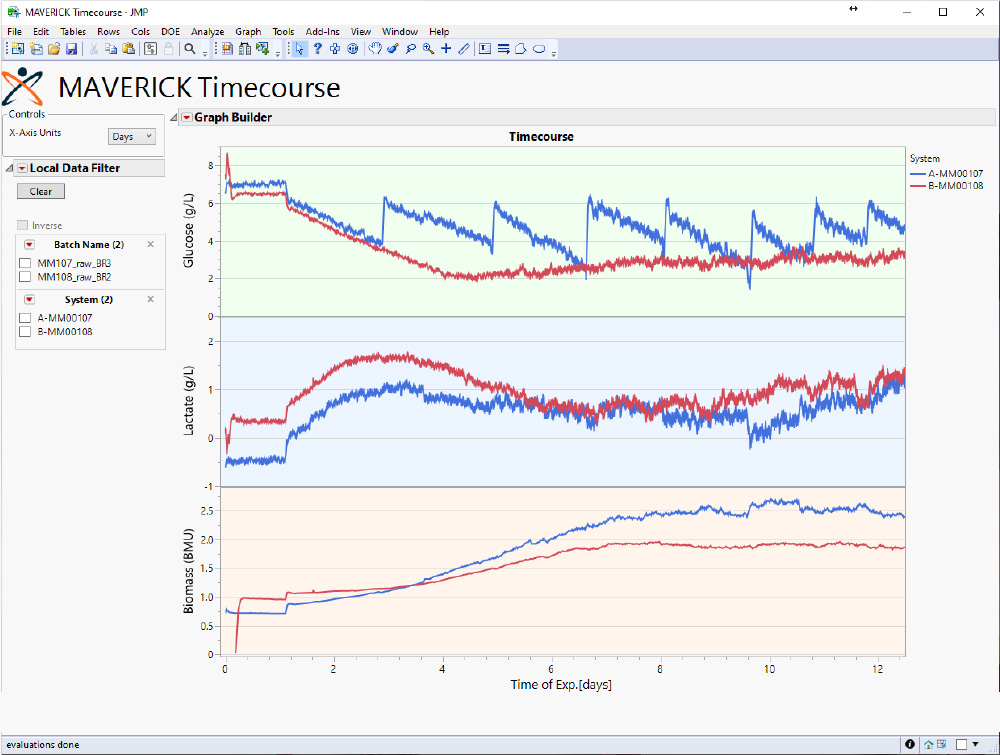

Data Visualization with MAVERICK and JMP Software

MAVERICK users can quickly visualize time-course data and compare different runs using the JMP statistical software package. To access this functionality, download the add-in tool from the 908 Devices customer support portal, or obtain a trial version of the JMP software directly from the JMP site.

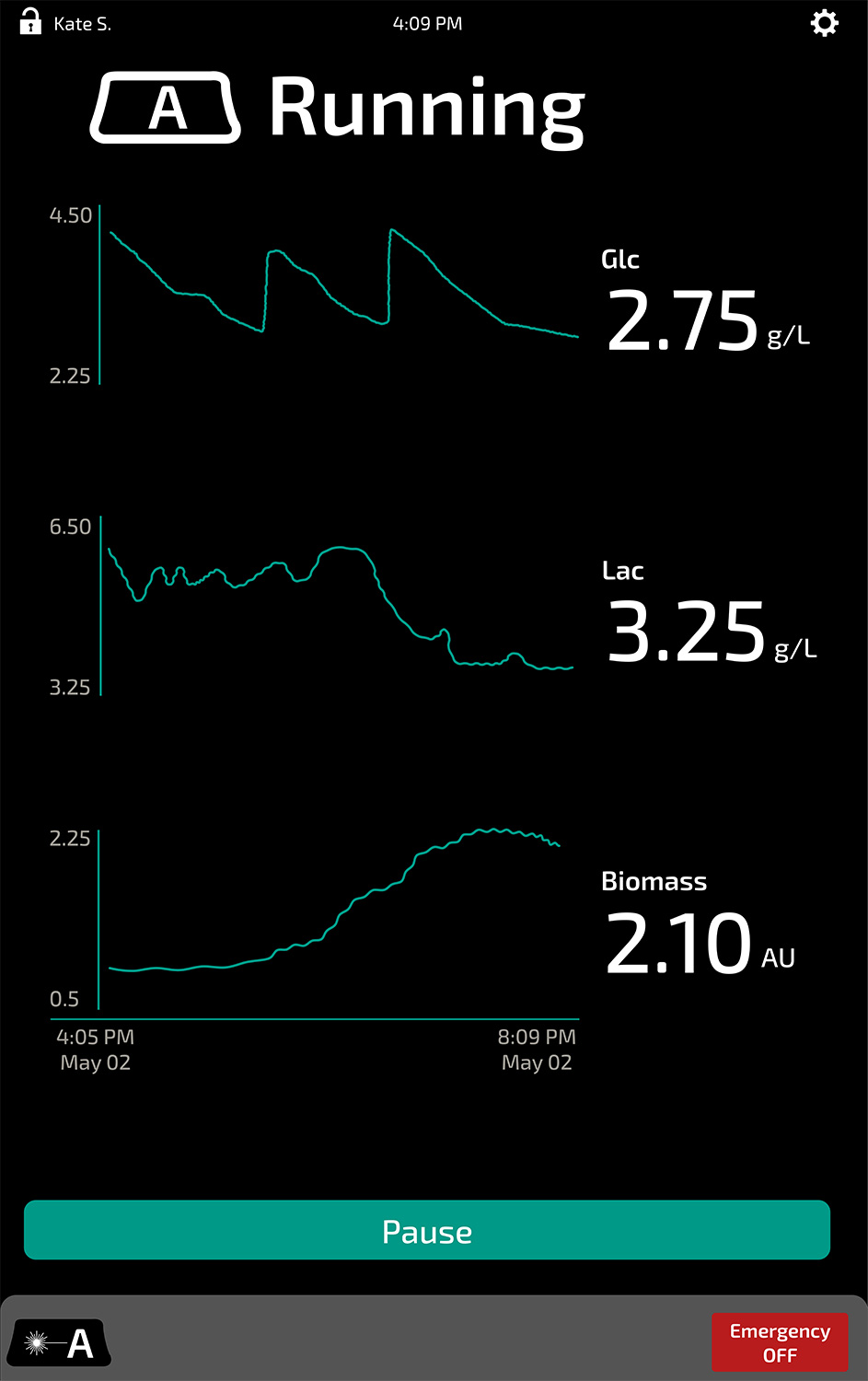

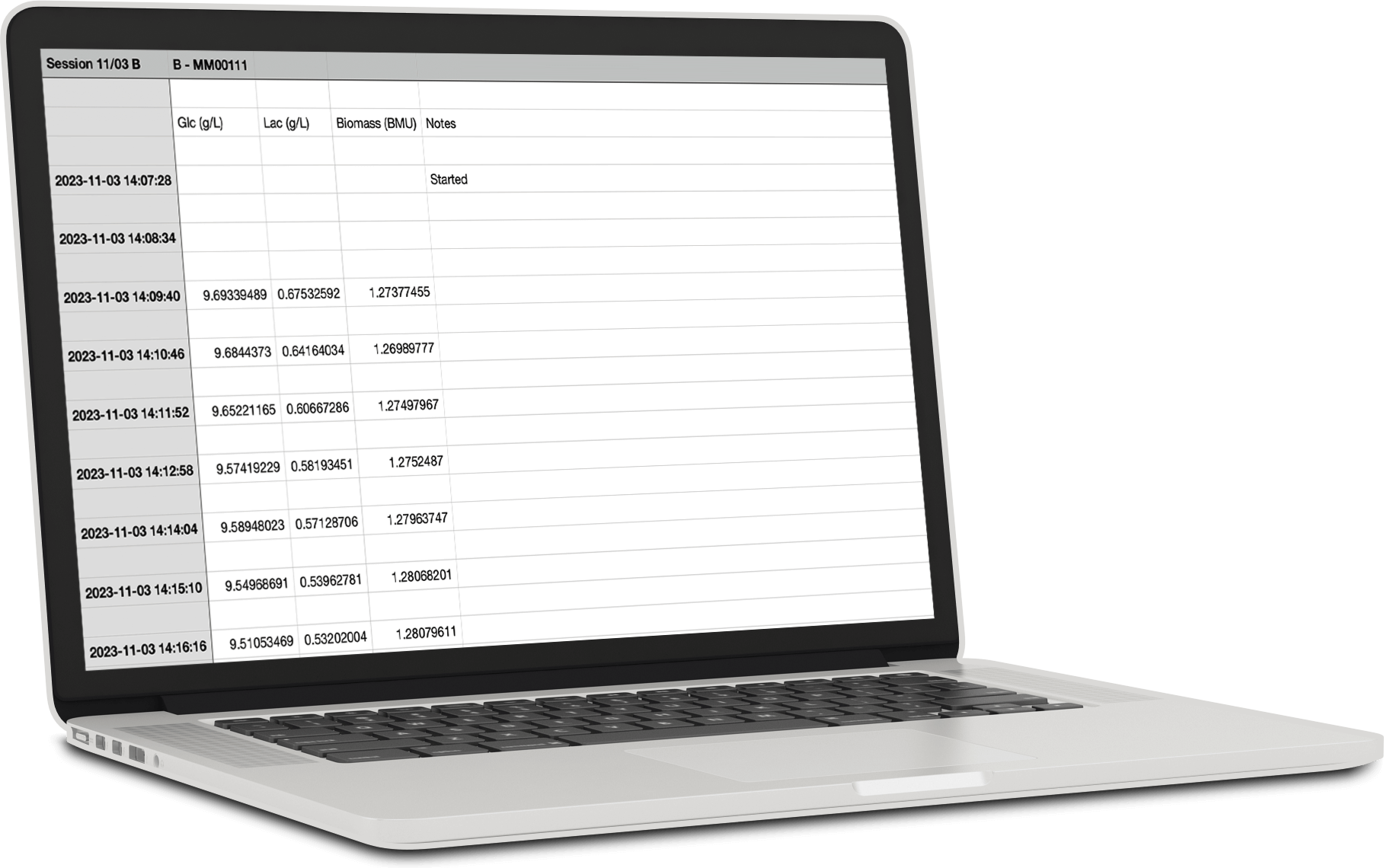

MAVERICK Data Processing

MAVERICK data files are rich in data from in-line measurements of glucose, lactate and biomass. The values in g/L, biomass units are provided in 1-minute intervals.

908 Devices Add-in, with JMP Statistical Discovery

Visualize time-course data for glucose, lactate, and biomass and compare runs.

MAVERICK Consumables & Services

Ensure your MAVERICK operates at peak efficiency with our range of consumables and services. We offer replacement immersion probes, calibration standards, Installation Qualification/Operational Qualification (IQ/OQ) support, and comprehensive service plans designed to maintain your favorite process analytical technology tool in optimal condition.

How Will You Use MAVERICK?

With MAVERICK you get in-line, real-time, and robust bioreactor monitoring of multiple key process parameters in biopharmaceutical manufacturing of monoclonal antibodies, recombinant proteins, and viral vectors utilizing CHO and HEK293 cell lines in a variety of media types.

Featured Resources

MAVERICK Brochure

Real-time bioprocess monitoring and control, right out of the box. In-line measurements of multiple critical parameters across media, across processes, across mammalian cell lines, across scales.

Instant Implementation of Raman-based Monitoring and Control for Key Upstream Bioprocessing Parameters

Instant Implementation of Raman-based PAT With MAVERICK for Monitoring Glucose and Lactate

MAVERICK is easy to set up and enables instant implementation of PAT generating accurate, precise, linear and selective in-line measurements across a wide range of media used typically in mammalian (including CHO and HEK293 media) cell culture for the production of biotherapeutics.

De novo Models for Raman: Comparison to and Advantages Over Traditional Chemometrics Models

Learn how the de novo model eliminates the need for complex empirical calibration models, reagents, or unreliable auto-sampling systems for in-line bioreactor monitoring.

Customer Support Portal

The My 908 portal gives scientists quick access to important resources like the latest software upgrades, product guides, and training materials.

Frequently Asked Questions

What applications can MAVERICK be used for?

MAVERICK is intended for bioprocessing applications in process development and biopharmaceutical manufacturing, enabling cell culture automation in biologic production for CHO or HEK293 mammalian cell line and media. For example, MAVERICK can help optimize viral vector titer in lentiviral vector production, AAV production, and other viral vector manufacturing applications.

Which cell lines and cell culture media does MAVERICK work with?

MAVERICK works with CHO and HEK293 cell lines and media.

Which bioreactors are compatible with MAVERICK?

MAVERICK autoclavable immersion probe is 220 mm long with 12 mm outside diameter, making it compatible with most 250 mL to 10L bioreactors. The PG 13.5 compression fitting interfaces with the standard bioreactor sensor ports and enables adjustment of the immersion depth (minimum 40 mm immersion depth is required).

I simultaneously operate more than one bioreactor. Can I multiplex MAVERICK to multiple vessels?

Yes. Each MAVERICK Hub connects and controls up to six Measurement Modules, supporting up to six individually or jointly operated bioreactors. Unlike other process Raman spectroscopy analyzers that employ optical switches or multi-channel design, MAVERICK preserves operational redundancy in multi-bioreactor applications.

How is MAVERICK calibrated?

The probe is calibrated using the two standards in the Calibration Kit. Calibration is performed prior to autoclaving the probe, before each bioreactor run. Each probe has a built-in memory chip that stores its calibration coefficients and verifies that the correct probe was re-attached post-sterilization.

How does the feedback control loop automate substrate feeding based on in-line measurements?

On-board analog/digital controller offers optional direct control of feed pumps. Alternatively, the measured values can be sent to an existing bioreactor controller, SCADA, or data acquisition system via Analog outputs or OPC UA protocol.

How are probes sterilized?

Probe barrels are autoclavable or steam sterilizable and should be replaced after 10 autoclave cycles to ensure the probe maintains its integrity.

Why doesn’t MAVERICK require the development of multivariate models to correlate Raman spectra to cell culture process parameters?

Normally, interpreting the spectrum from Raman spectroscopy requires the development of empirical multivariate calibration models (chemometric modeling) specific to analytes of interest. This requires multiple bioreactor runs to acquire real-time spectral data, manually collect numerous samples from the bioreactors for at-line/off-line analysis, and then utilize statistical analysis to correlate the Raman spectra to the at-line/off-line measurements. Naturally, this process is very time consuming, expensive, and complicated, making Raman-based bioprocess monitoring inaccessible to most biopharma labs.

MAVERICK purpose-built De Novo Model does not need to be trained on empirical process data. The model quantifies analyte concentration by accurately inferring peaks, associated with the analytes of interest based on a priori knowledge and the baseline from water, other mixture components, and instrumentation in the spectra.

Is MAVERICK available outside the United States, and do you provide global technical support?

MAVERICK devices and support are available for purchase directly from 908 Devices in North America and Europe, and through a network of distributors globally.

email Subscribe to Our Communications Signup to receive new product updates, technical tips and more.