Cell Therapy

Robust Cell Therapy Manufacturing

Enhance process understanding, optimize process performance, and ensure batch-to-batch reproducibility in cell therapy manufacturing with easy-to-use PAT tools.

Overcoming Manufacturing Challenges in Cell Therapy

Cell therapy is increasingly becoming a viable therapeutic alternative to traditional treatments for a wide range of diseases. However, the complexities of manufacturing process characterization and control severely limit their availability and wide adoption. Dealing with the variability of starting materials, meeting strict manufacturing timeframes, and maintaining compliance with Current Good Manufacturing Practices (cGMP) make it difficult to develop and implement a robust manufacturing process. Transitioning away from manual manufacturing protocols and towards adaptive process strategies requires careful monitoring and control of critical process parameters (CPPs) with the help of at-line, on-line, and in-line Process Analytical Technologies (PAT).

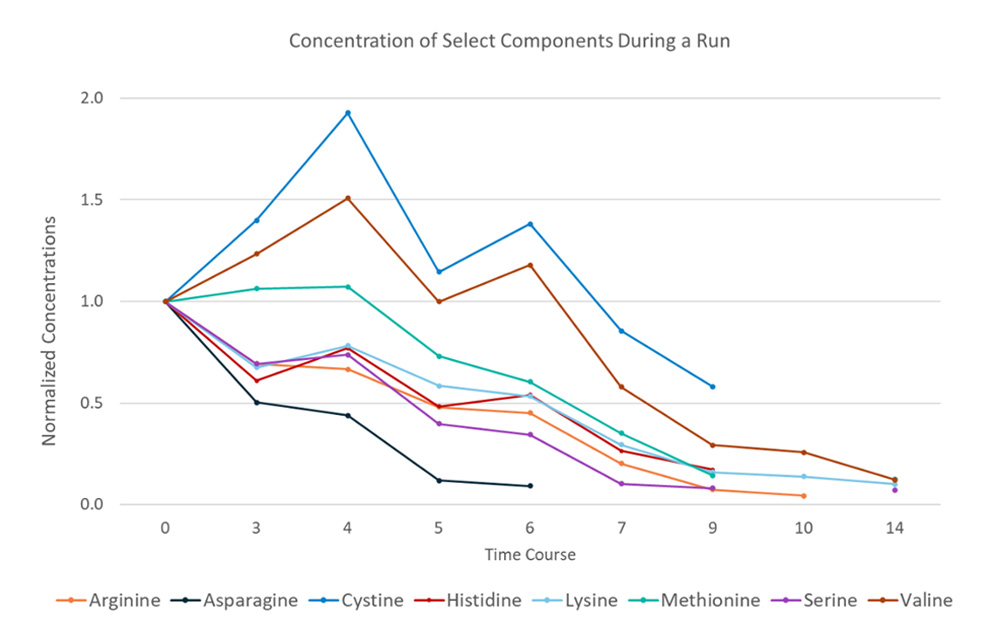

At-line Monitoring of Amino Acids

Amino acids are critical to cellular function and viability, but different cells may consume them at different rates. Monitoring concentrations of amino acids during cell expansion helps prevent their depletion that may cause a batch failure.

Real-time Glucose Monitoring

Glucose is the primary energy source and its concentration in the media regulates metabolic pathways and is linked to proliferation, metabolites production, and phenotype expression. Continuous glucose measurement can be used for control of substrate feeding or media exchange pumps.

Continuous Lactate Monitoring

Excessive accumulation of lactate can inhibit cell growth and decrease cytokine secretion. It can also be used to estimate cell count, predict cell expansion rate, determine optimal harvest time.

In-line Biomass Measurement

In-situ Total Cell Density (TCD) measurement can be used to ensure that appropriate cell densities are achieved, especially in adherent cell cultures where cell counting is difficult to perform.

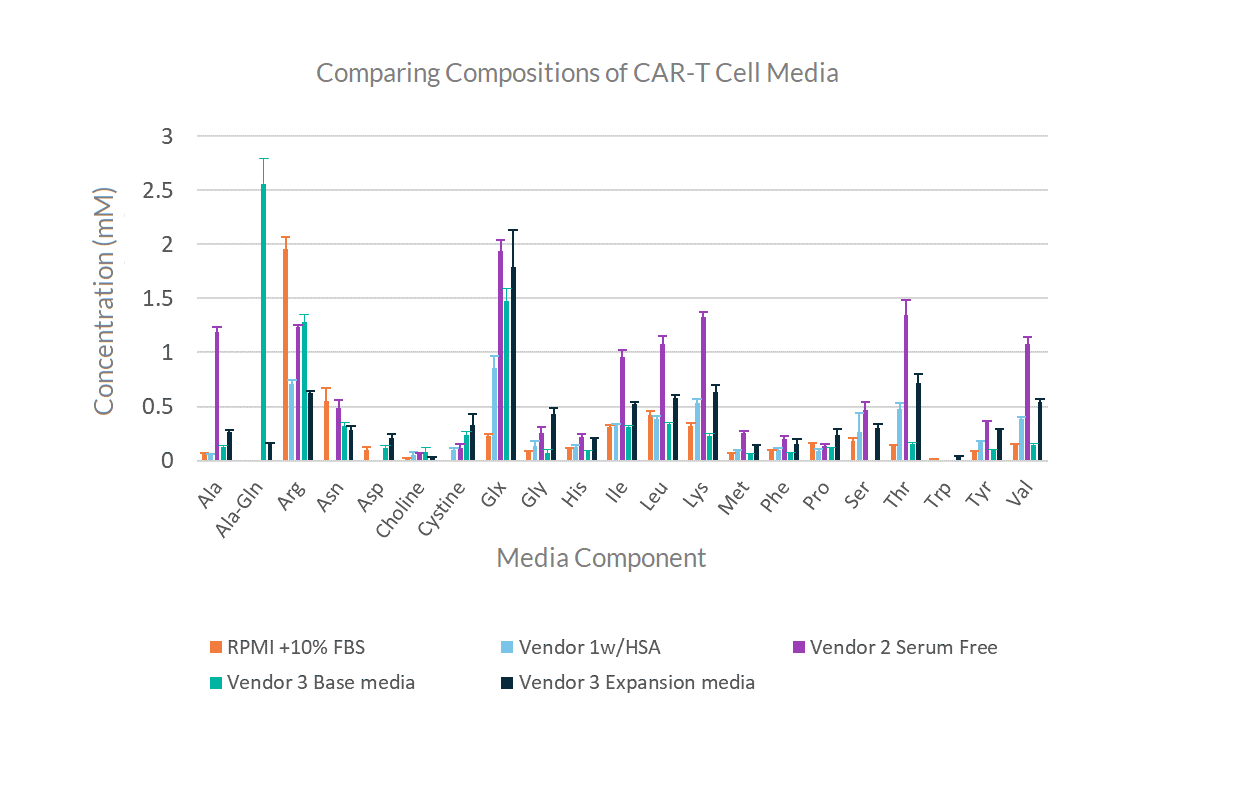

Cell Therapy Media is Critical

Cell therapy that utilizes primary and stem cells introduce distinct challenges in the selection, development, and optimization of media. The degree of cell expansion, differentiation, and functional activation achieved ex vivo can differ markedly across patients and between donors. Given that the formulation of cell culture media directly influences critical cell characteristics—including growth rates, health, and functional capabilities—it’s imperative to comprehensively assess how different media components affect the Critical Quality Attributes (CQAs). These attributes play a pivotal role in determining the therapeutic effectiveness of cell therapy.

Media Fingerprinting & Screening

Screen and compare commercially available cell therapy media and ensure consistency of media formulations from run to run. With REBEL, you get at-line media analysis of 30+ components in under 10 minutes.

Accelerate Media Optimization

Developing and optimizing media formulation necessitates careful monitoring of key nutrients’ consumption, metabolite production and their collective effects on process efficiency and product quality attributes. Waiting weeks for cell culture media analysis results is not feasible. REBEL provides a solution with its rapid analysis turnaround time, small sample volumes, and minimal sample prep.

Real-time Monitoring Can Make a Big Impact on Your Process

Ensure Process Robustness with Real-Time Monitoring

A well-characterized and controlled production process is crucial for effectiveness of cell therapy and necessitates integration of Process Analytical Technology (PAT) solutions with automated cell therapy manufacturing systems. MAVEN and MAVERICK easily integrate with cell therapy manufacturing systems and deliver continuous monitoring and control of critical process parameters (CPPs) such as glucose, lactate and total biomass, enhancing process understanding, ensuring robustness and reducing human intervention. With REBEL amino acids concentrations in the media can be frequently monitored during cell expansion processes to ensure that any variations in cell growth and health were not due to unknown changes in expected media formulation.

Timely Process Insights in Cell Therapy Manufacturing

Our suite of devices provides at-line, on-line or in-line monitoring for cell expansion process.

Implement Process Analytical Technology (PAT) in Your Cell Therapy Workflows

Historically, automated cell therapy manufacturing systems had limited real-time monitoring capabilities due to lack of robust and compatible process analytical technologies. MAVEN and MAVERICK are offered with a variety of single-use and reusable process interfaces and multiple analog and digital communication options making integration possible with a number of manufacturing automation systems.

For Cell Culture Media Analysis

REBEL

Analyze fresh or spent media and get quantitative reports for amino acids, dipeptides, water soluble vitamins and biogenic amines.

For Glucose & Lactate

MAVEN

Get valuable insights and control from real-time glucose and lactate monitoring without the loss of bioreactor or fermenter volume.

For Bioprocessing

MAVERICK

Raman-based, in-line monitoring and control of multiple bioprocessing key process parameters in up to six bioreactors simultaneously.

Suggested Resources

In-Process Analytics are Key to Successful Cell Therapy Process Optimization and Manufacturing

Considerable clinical activity and the approval of several autologous, patient-specific therapies has increased industry demand and has also highlighted bottlenecks in manufacturing workflows.

Glucose and Lactate Raman-Based Monitoring With MAVERICK: Performance in Spent Media

MAVERICK provides a plug-and-play, in-line, Raman based PAT solution for monitoring and control of glucose, lactate, and biomass in up to 6 bioreactors. This Application Snapshot shows the results from experiments to demonstrate the selectivity of glucose and lactate measurements from MAVERICK in complex spent media samples from CHO and HEK293 cultures.

REBEL Brochure

The REBEL is a novel, dedicated cell culture media analyzer designed for rapid, easy, and efficient amino acid and nutrient analysis.

MAVEN Brochure

MAVEN offers monitoring and control of glucose and lactate concentrations during cell culture and fermentation. Download this brochure to learn more.

MAVERICK Brochure

Real-time bioprocess monitoring and control, right out of the box. In-line measurements of multiple critical parameters across media, across processes, across mammalian cell lines, across scales.

Cell Therapy Collaboration Announcements

908 Devices and Terumo BCT

908 Devices and Terumo Blood and Cell Technologies collaborate to add on-line analytics to Quantum Flex cell therapy expansion systems.

908 Devices and Cellares

908 Devices and Cellares are collaborating to integrate our MAVERICK in-line analyzer into Cellares’ Cell Shuttle, a fully integrated cell therapy manufacturing platform.

email Subscribe to Our Communications Signup to receive new product updates, technical tips and more.