Bioprocess Analytics

Faster Insights

Better Control

Gain actionable insights with real-time monitoring and control of critical bioprocess parameters to improve product quality and increase process robustness and efficiency.

Measure What Matters,

When It Matters

Real-time measurements in upstream bioprocessing are traditionally limited to just a few parameters such as pH, dissolved oxygen, temperature, and agitation speed. Other critical process parameters such as glucose, lactate, and amino acid concentrations are often based on infrequent manual sampling and at-line or off-line analysis at a core or external lab.

Driven by PAT and the demand for greater efficiency, process development teams need more data closer to the point of need.

Take Control of Your Bioprocess: Optimize Process Productivity

Bioprocess control enabled by frequent measurements has been shown to improve process productivity. Continuous monitoring and control with a digital record can also reduce manual sampling and human error. The biopharmaceutical industry is moving to continuous manufacturing. This poses increased requirements for PAT to support real-time monitoring and control for intensification. Knowing the state of your cell culture at all times enables instant, automated response. Take control of your bioprocess today and enhance your process for optimal results.

Your Choice for Ultimate Bioprocess Monitoring and Control

Our suite of devices provides the data you need, where and when you need it.

Less Data = Greater Risk

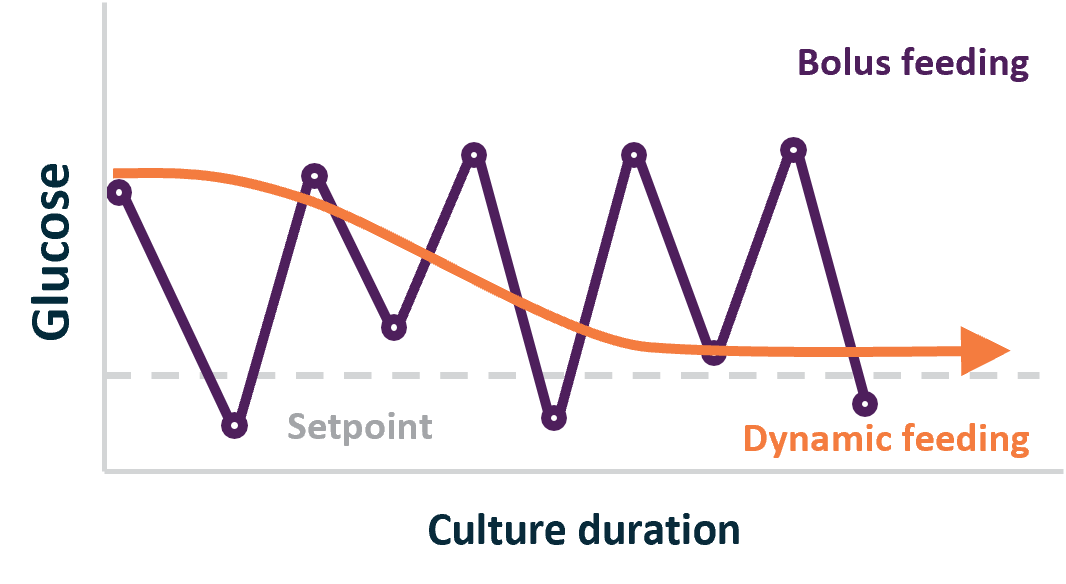

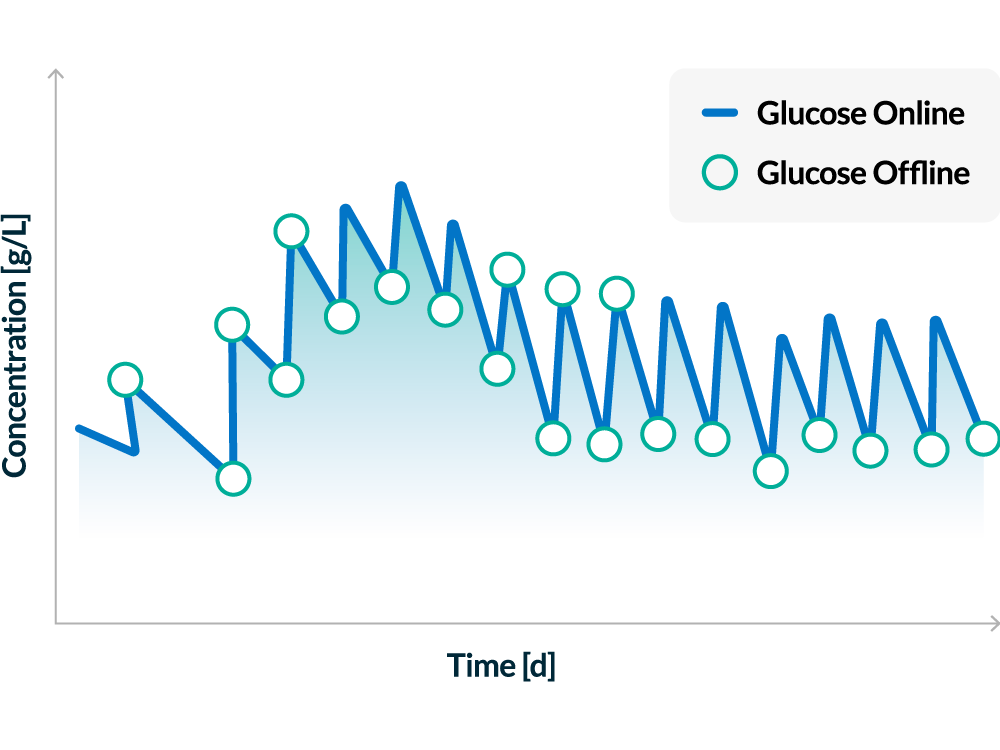

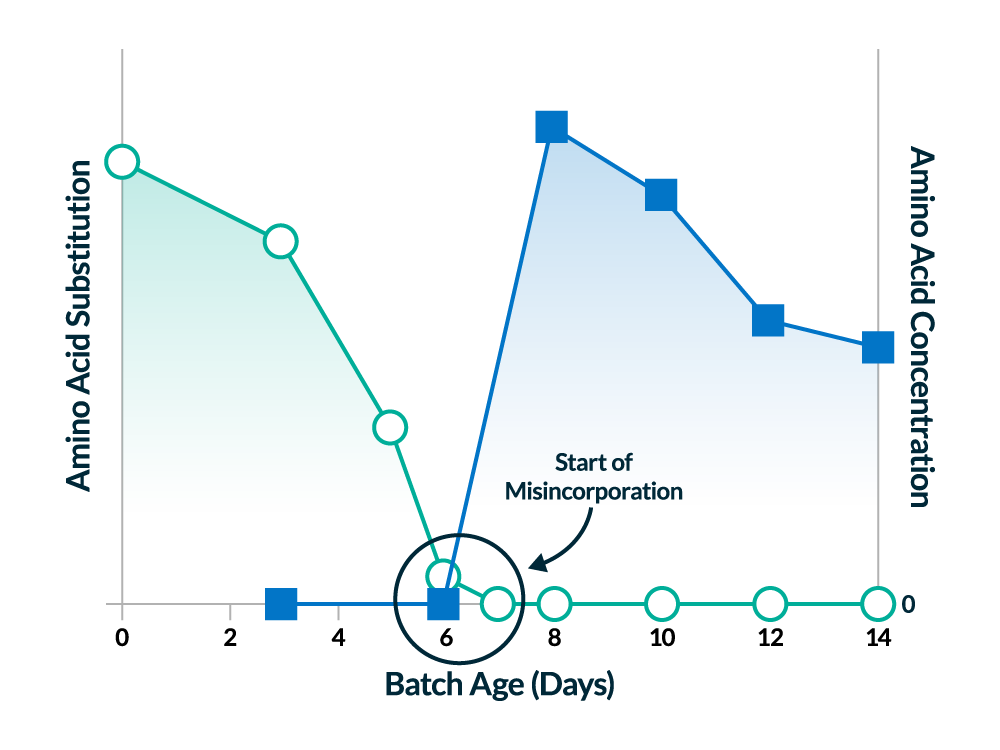

Having long gaps between measurements hinders the ability to control a bioprocess. Critical process deviations may go unnoticed and uncorrected for hours or days.

An incomplete picture: The periodic offline glucose data points shown above paint an incomplete picture of glucose concentration trends. By contrast, the online, continuous measurement reveals much more detail and process knowledge.

Hidden process errors: Without frequent spent media analysis, errors like the misincorporation of an amino acid (shown above) would be invisible during process development

Real-time Monitoring Can Make a Big Impact on Your Process

For Bioprocessing

MAVERICK

Raman-based, in-line monitoring and control of multiple bioprocessing key process parameters in up to six bioreactors simultaneously.

For Cell Culture Media Analysis

REBEL

Analyze fresh or spent media and get quantitative reports for amino acids, dipeptides, water soluble vitamins and biogenic amines.

For Glucose & Lactate

MAVEN

Get valuable insights and control from real-time glucose and lactate monitoring without the loss of bioreactor or fermenter volume.

For Methanol or Ethanol

TRACE C2

Monitor methanol or ethanol and automatically control substrate feeding in microbial fermentation.

Suggested Resources

Methanol Dialysis

The online analyzer TRACE C2 Control allows a rapid and precise determination of the methanol concentration in the fermenter and provides the tools for a quick set-up of a feed control strategy

MAVEN Brochure

MAVEN offers monitoring and control of glucose and lactate concentrations during cell culture and fermentation. Download this brochure to learn more.

Instant Implementation of Raman-based PAT With MAVERICK for Monitoring Glucose and Lactate

MAVERICK is easy to set up and enables instant implementation of PAT generating accurate, precise, linear and selective in-line measurements across a wide range of media used typically in mammalian (including CHO and HEK293 media) cell culture for the production of biotherapeutics.

Empowering Process Optimization for a mAb-Expressing CHO Cell Line

Coupling miniature mass spectrometry (MS) with microchip capillary electrophoresis (CE) fulfills an unmet need: simple, rapid at-line nutrient quantitation.

email Subscribe to Our Communications Signup to receive new product updates, technical tips and more.