For over 40 years, Dr. Dave Schiering has been at the forefront of FTIR technology, contributing to groundbreaking advancements in spectroscopy. Dr. Schiering first discovered IR and Raman spectroscopy in grad school, where he immediately saw advantages over older dispersive methods. His career then took him to Perkin Elmer, where he played a pivotal role in developing the Model 1600, a leading FTIR instrument for analytical labs at the time. In recognition for his significant contributions to vibrational spectroscopy, Dr. Schiering was selected as the 2025 recipient of the Williams-Wright Award by the Coblentz Society.

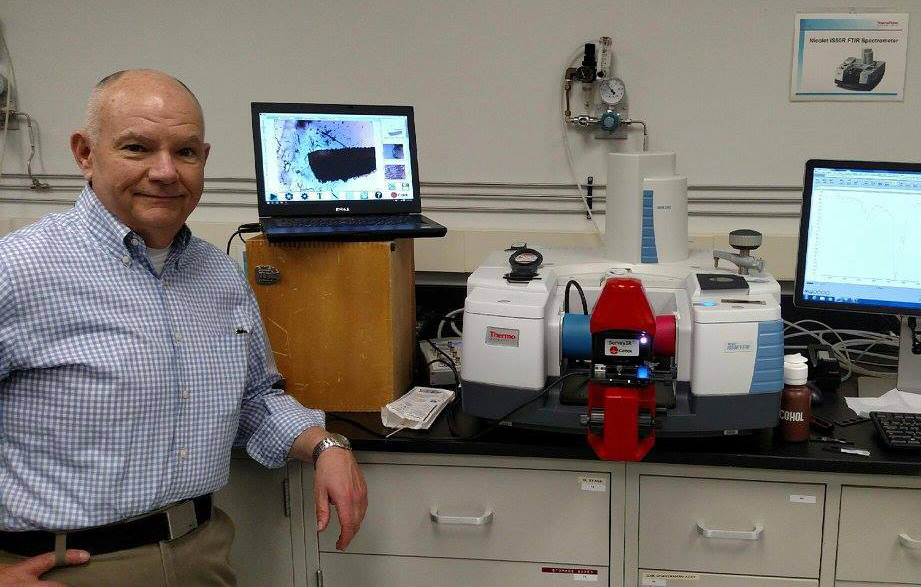

As the former managing partner and Chief Technology Officer of RedWave Technology and – following an acquisition — the current 908 Devices Fellow, we sat down with Dr. Schiering to discuss his perspective on the progression of FTIR technology through the decades, and his vision for its future.

How has FTIR technology evolved over your 40+ year career?

“When I first started, FTIR was definitely the pricier option compared to dispersive spectroscopy. But over time, we’ve seen FTIR become more affordable, sensitive and faster, which has really opened the door for more labs and industries to use it. It’s now more common than ever, with instruments designed to be smaller and faster, and software becoming much more user-friendly. I’ve also witnessed multiple kinds of applications, from life sciences to field forensics.

Beyond the Model 1600, which I’ll come back to, a key moment in FTIR’s evolution came after 9/11, particularly with the anthrax letters. Responders were faced with the daunting task of dealing with white powders in places like courthouses and malls. The urgent need for reliable, on-the-spot identification tools created a huge market for FTIR products. Hazmat teams needed solutions that could quickly and safely analyze these powders, which directly led to the development of portable field forensics technology.

The introduction of Smiths Detection’s HazmatID in 2003 also marked a major advancement. It was compact, durable and the first FTIR device to use lithium-ion batteries and be waterproof. Over its 20-year run, more than 8,000 of these instruments were sold, making them a standard piece of equipment on HAZMAT trucks in major cities.“

What were some of the key challenges and breakthroughs in the early development of FTIR spectroscopy?

“When I started my career, you really needed a solid understanding of the science behind spectroscopy to use the equipment. At a minimum, people needed a chemistry degree, and PhD-level spectroscopists often had to offer guidance at satellite labs. Interpreting parameters was a manual process, and you had to know exactly how those variables impacted the spectrum you were recording. It required a deep technical knowledge to get reliable results.

Today, that process is largely automated or embedded within software, so users don’t need as much in-depth training. The development of smarter instruments and optimized workflows has made it easier for less specialized users to operate the systems, but the tricky part is finding a balance—making the technology accessible without losing its power.“

The Model 1600 FTIR spectrometer was a market-changing product. What made it so successful and how did it impact laboratories?

“The Model 1600 replaced older, slower, and less sensitive dispersive IR models at a significantly lower cost. I was fortunate to work on the Model 1600; in fact, it’s probably the most successful project I’ve ever worked on, with over half a billion dollars in market penetration. By drastically reducing the price, we made FTIR technology more accessible and widespread.

Unlike our closest competitor’s floor-mounted model, which was twice as expensive, the Model 1600 was compact and desktop-sized. While it wasn’t as miniaturized as today’s standards, but its smaller size and affordability were key to its impact. The device opened up opportunities for a diverse range of laboratories, from QC and analytical services labs to forensic science labs, and chemistry education, which had previously been limited by the constraints of dispersive technology. It simplified FTIR technology, making high-quality data accessible to a broader audience.“

You’ve led the development of various optical accessories and microscopes for FTIR spectroscopy. How have these innovations contributed to the broader adoption of FTIR in different industries?

“The introduction of vibrational microscopic spectroscopy during my graduate years brought a huge shift, particularly in analytical services, as these innovations allowed us to work on a much smaller scale and analyze samples more precisely. I’ve also been deeply involved in developing optical accessories like gas phase analysis tools and ATR (attenuated total reflection) devices, which expanded the versatility of FTIR. Forensic applications, such as trace analysis for fiber evidence and drug analysis, became more efficient with these advancements.”

What does the future hold for FTIR technology and how is it being applied today? Are there any emerging trends or technologies you find particularly exciting?

“Miniaturization will continue to advance, focusing on making instruments smaller and lighter while maintaining performance. The Department of Defense (DoD) is particularly interested in integrating these miniaturized systems for continuous monitoring and unified operations, utilizing a “one pane of glass” approach where multiple sensors contribute to a combined operational picture. While it’s unclear if this will bring prices down, lab instruments are already more affordable—some are now half the price of older models.

FTIR and Raman spectroscopy are being applied across various fields, from traditional QC analytical services to cutting-edge research like disease diagnosis at the cellular level. While FDA approval for diagnostic use is still pending, the potential of these technologies is evident. Forensics, government and environmental monitoring also rely heavily on FTIR and Raman spectroscopy, and I believe they will remain essential methods for years to come, particularly across different material states, including vapor.

I would be remiss not to mention AI, with efforts to enhance or even replace traditional spectral libraries. AI has the potential to predict spectra and store libraries directly in devices, making it easier to identify substances and detect new threats faster.”

Dr. Dave Schiering’s career illustrates FTIR’s evolution from a high-cost tool to a versatile and accessible technology. Today, advancements in miniaturization and AI promise to further enhance its impact and accessibility across multiple fields, from life sciences to field forensics. To learn more about 908 Devices’ utilization of FTIR and other spectroscopy methods, please visit: https://908devices.com/applications/chemical-detection/.