The Rebel Analyzer Enables Real-Time Comprehensive Media Analysis in a Benchtop Package

Spent media analysis is a critical part of biotherapeutic process development. The ability to analyze how cell culture components are consumed provides data that speaks to the health and productivity of the culture itself. The data generated allows multiple groups within process development to work together to ensure the best overall process; this includes cell line development, media formulation, process optimization, and purification.

While process development projects rely heavily on this information, it can be challenging to obtain. Most often, groups involved in process development do not have the analytical tools or resources required for this type of analysis. This means that culture samples need to be sent out to on-site or off-site core labs. Outsourcing can take days to weeks from sample-to-result and thus severely delaying process development efforts.

A better solution is at-line spent media analysis. Real-time analysis supports process analytics technology (PAT) initiatives through monitoring and maintaining critical quality attributes to ensure product quality and batch-to-batch consistency. Waiting until the end of a culture run for spent media analysis results does not inform operators about the process daily. Running this analysis in real-time speeds process development and permits the ability to affect change in real-time instead of having to wait for the next run to implement changes.

As an alternative to outsourcing, biochemical analyzers can provide data quickly. Still, they are limited to a smaller number of analytes. This provides an incomplete picture, which often results in samples being sent to core labs for comprehensive spent media analysis of amino acids and other media components.

Another challenge is the large number of samples generated when using a microbioreactor system. The development of  scaled-down bioreactor models for process development has been a breakthrough in that they permit simultaneous testing of many different culture conditions in a fraction of the time. However, the number of samples generated is substantial, and the volume of these microbioreactors is small, thus creating another bottleneck and limiting the ability to run samples daily.

scaled-down bioreactor models for process development has been a breakthrough in that they permit simultaneous testing of many different culture conditions in a fraction of the time. However, the number of samples generated is substantial, and the volume of these microbioreactors is small, thus creating another bottleneck and limiting the ability to run samples daily.

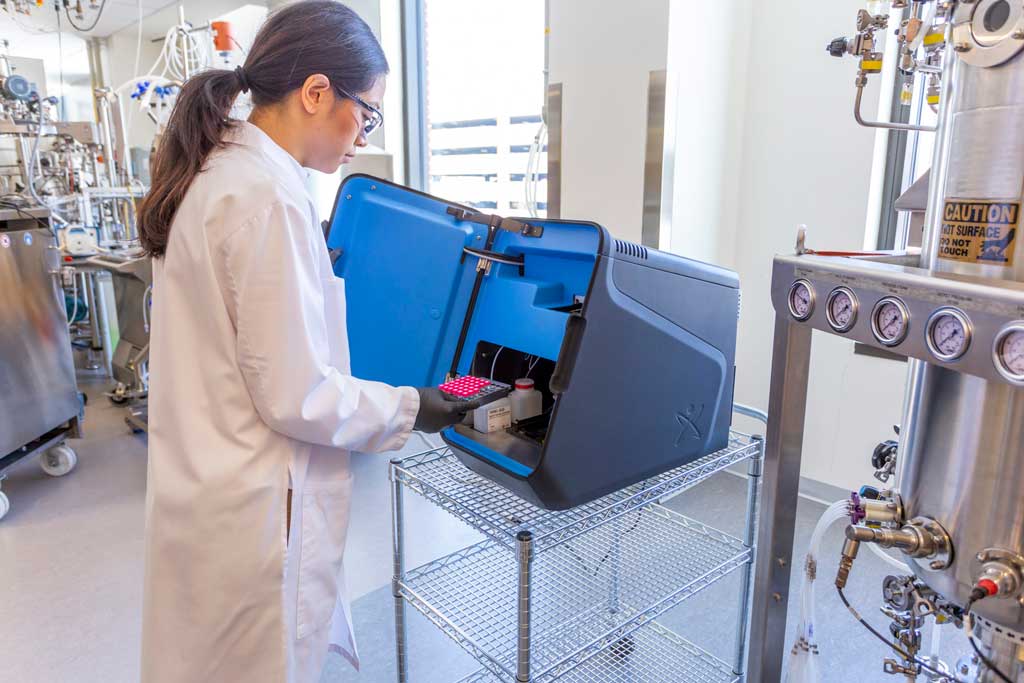

To speed process development using real-time analytics, 908 Devices launched its Rebel analyzer. The Rebel™ provides comprehensive at-line fresh and spent cell culture media analysis for bioprocess labs. This offers a high-throughput solution for media analysis.

Key Benefits of the Rebel System:

Comprehensive analysis

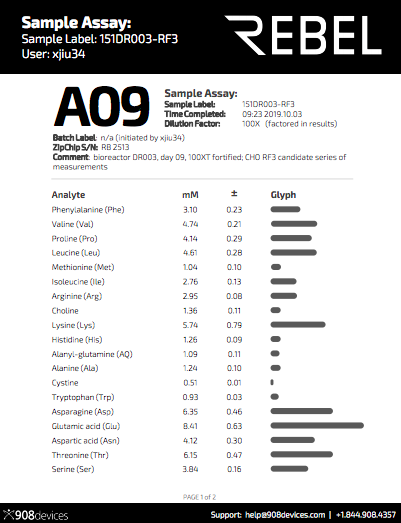

The Rebel analyzer can quantitate over 30 components in cell culture media, including amino acids, dipeptides, water-soluble vitamins, and amines.

Speed

At-line results for quantitative tests enable real-time decision-making when compared with days or weeks for results from core labs.

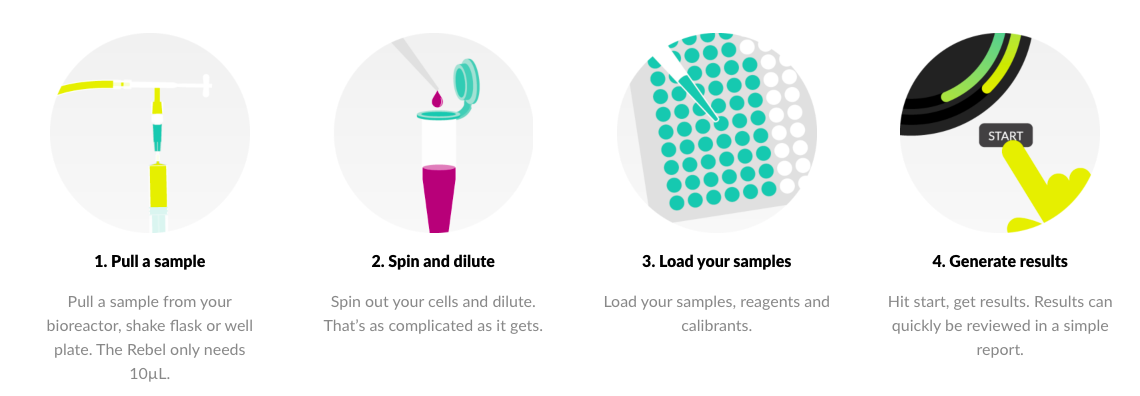

Simplified workflow

Four simple steps are all that is needed to complete analysis.

Ease of use

The Rebel analyzer is easy to use, and its small footprint permits flexibility in the lab layout. Reagents are premixed, and each kit comes with electrolyte, diluent, standards, sample plates, and a chip – everything needed to run 200 samples. It is label-free, and there is no specialized training required. The intuitive user interface and touchscreen make operating the Rebel a simple task.

Speed process development time with real-time reporting

Real-time analytics allows process development labs to keep up with aggressive development schedules. Contemporaneous decisions can be made since analysis is quick, and data is automatically processed and collated at the end of each run.  Reports on analytes detected and their concentration can be uploaded to network drives for remote access and are in non-proprietary formats for integration in LIMS systems.

Reports on analytes detected and their concentration can be uploaded to network drives for remote access and are in non-proprietary formats for integration in LIMS systems.

Rebel Applications

There are a host of applications for the Rebel analyzer with specific examples and workflows explained in available case studies.

Case study examples include:

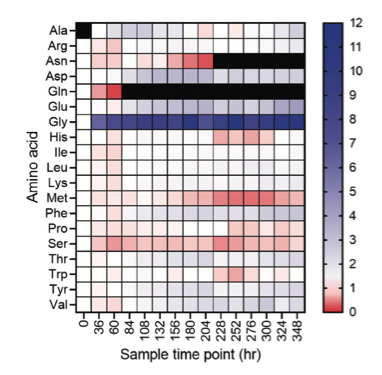

Spent media analysis with a parallel microbioreactor system

In one publication titled “Spent media analysis with an integrated CE-MS analyzer of Chinese hamster ovary cells grown in an ammonia-stressed parallel microbioreactor platform,” authors describe how spent media analysis was conducted using the Rebel with a parallel microbioreactor system. When using a microbioreactor system, there are only small volumes available for sampling. The Rebel’s integrated capability permitted minimal sample volumes to be analyzed rapidly. Traditional analytic approaches were not able to discern significant changes between the cultures, especially early in the processes, despite dramatic differences in the measured titer. The researchers discovered particular nutrients that were underfed during the process, which may have led to issues with productivity.

Routine serum-supplemented media analysis

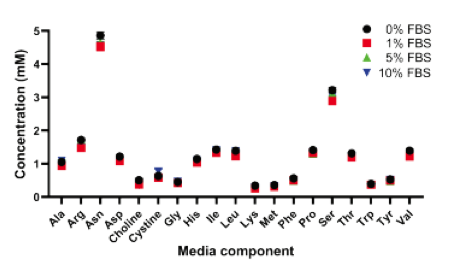

In another study, the nutrient composition of a commercially available chemically-defined media was supplemented with fetal bovine serum (FBS) at various concentrations (0% – 10%). FBS is still utilized in cell culture since it supplies several growth factors necessary for specific initial research processes. Due to the high levels of serum proteins introduced into the media, there may be interference with the detection of smaller sized nutrients when traditional approaches are used.

The Rebel showed no interference concerns on the media tested, which contained levels of up to 10% FBS supplemented in.

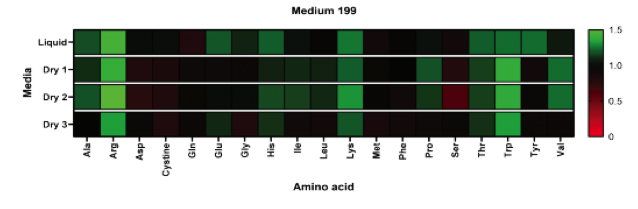

Media optimization during preparation

This study demonstrates how the Rebel can be used to ensure that the media is prepared correctly. As processes scale-up, using off-the-shelf liquid media is costly and impractical. Premixed dry formulations are easier to transport and store. Variability may be introduced upon hydration, so the Rebel was used to run freshly prepared dry blends and compared the values to the corresponding off-the-shelf liquid cell media. The analysis revealed that specified nutrients deviated in value from the expected levels depending on the dry formulation tested. It would be essential to note these variations before being used in a culture so that if any changes in cell health or productivity are observed, it might be correlated to the initial media preparation.

For more information, please see Rebel Analyzer.